Removal Procedure

|

At operating temperature, the hydraulic oil is hot and under pressure. Hot oils can cause burns. To prevent possible personal injury, release the pressure in the implement hydraulic circuit (boom, stick, bucket, and swing), travel circuits, and the hydraulic oil tank at the filler cap before any hydraulic lines or components are disconnected or removed. Remove the filler cap only when the engine is stopped and the filler cap is cool enough to touch. |

|

|

| NOTICE |

|---|

|

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids. Refer to Special Publication, NENG2500, “Caterpillar Tools and Shop Products Guide” for tools and supplies suitable to collect and contain fluids on Caterpillar products. Dispose of all fluids according to local regulations and mandates. |

|

|

Note: Put identification marks on all hose assemblies for installation purposes. Plug all hose assemblies. This helps to prevent fluid loss, and this helps to keep contaminants from entering the system.

- Fully extend the stick and the bucket. Lower the stick and the bucket to the ground.

- Release the hydraulic system pressure. Refer to Disassembly and Assembly, “Hydraulic System Pressure – Release”.

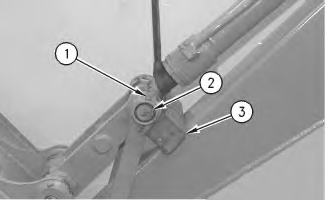

- Attach a suitable lifting device to the rod end of the bucket cylinder. Put a wood block (3) under the link assemblies as a support.

|

|

|

|

|

|

| Illustration 1 | g00535019 |

- Remove the nuts and retaining bolt (1). Remove pin (2) .

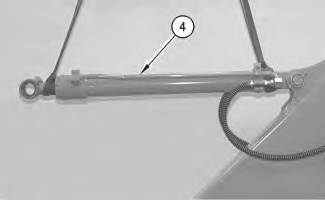

- Attach a suitable lifting device to the head end of the bucket cylinder. Raise bucket cylinder (4) until the cylinder is level.

|

|

|

|

|

|

| Illustration 2 | g00535026 |

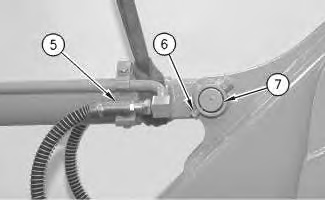

- Remove nuts and retaining bolt (6). Remove pin (7). Remove the bucket cylinder. The weight of the bucket cylinder is approximately 50 kg (110 lb).

- Remove the shims that are used at the pin joint for the bucket cylinder.

Note: Shims may be used between the stick and the bucket cylinder. These shims are used to adjust the lateral clearance between the components at the pin joint. Put identification marks on all shims for assembly purposes.