|

|

|

|

|

|

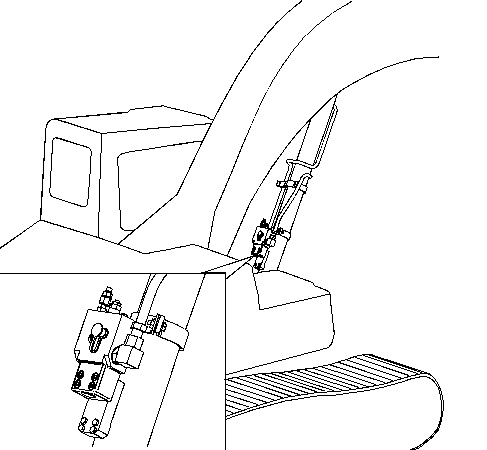

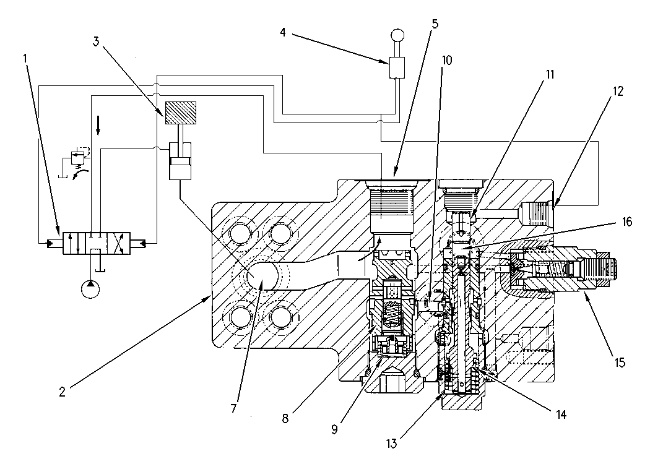

| Illustration 1 | g01027388 |

|

Location of boom lowering control valve |

|

The boom lowering control valve is located on the head end of the boom cylinder.

The boom lowering control valve has two functions:

- The boom lowering control valve prevents the boom from falling if a hydraulic supply line fails or if a supply tube to a boom cylinder fails.

- The boom lowering control valve allows the operator to manually lower the boom when the engine is shut down.

Reference: For information on lowering the boom manually, see Operation and Maintenance Manual, “Equipment Lowering with Engine Stopped”.

|

|

|

|

|

|

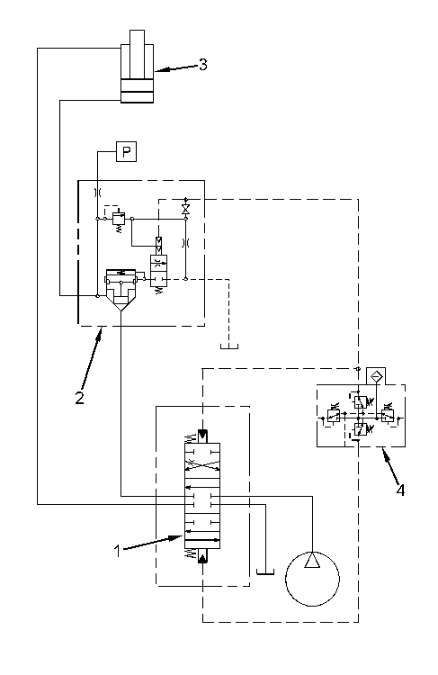

| Illustration 2 | g01028935 |

|

Simplified hydraulic schematic (boom lowering control valve) (1) Main control valve (boom I control valve) (2) Boom lowering control valve (3) Boom cylinder (4) Joystick |

|

BOOM RAISE Operation

|

|

|

|

|

|

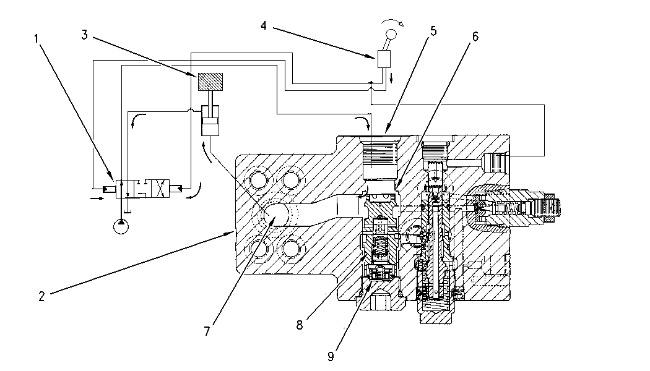

| Illustration 3 | g00795501 |

|

(1) Main control valve (2) Boom lowering control valve (3) Boom cylinder (4) Joystick (5) Inlet port (6) Sealing face (7) Outlet port to head end of boom cylinder (8) Spool 1 (9) Chamber |

|

When joystick (4) is moved to the BOOM RAISE position, the pump oil flows from main control valve (1) to boom lowering control valve (2). The pump oil flows through port (5). This will move spool (8) downward. Pump oil then flows through the passage to outlet port (7) and to the head end of boom cylinder (3). This causes the boom to raise.

BOOM LOWER Operation

|

|

|

|

|

|

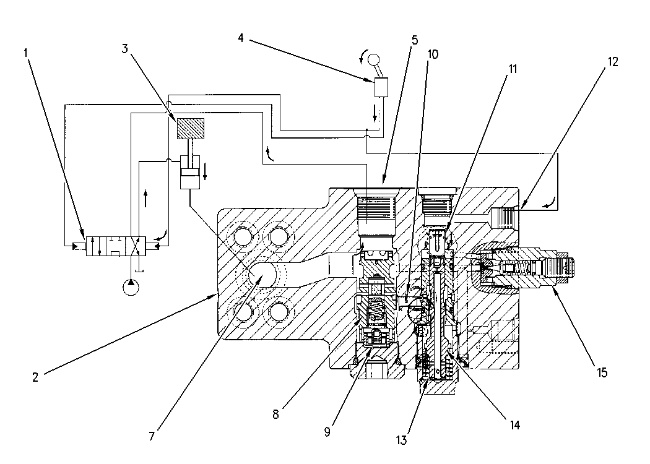

| Illustration 4 | g00795502 |

|

(1) Main control valve (2) Boom lowering control valve (3) Boom cylinder (4) Joystick (5) Inlet port (7) Outlet port to head end of boom cylinder (8) Spool 1 (9) Chamber (10) Passage to drain (11) Piston (12) Inlet port for pilot oil (13) Chamber (14) Spool 2 (15) Relief valve |

|

When joystick (4) is moved to the BOOM LOWER position, pilot oil flows from joystick (4) to port (12). This will move piston (11) downward. When piston (11) moves downward, hydraulic oil from chamber (9) flows through passage (10). This will allow spool (8) to open. Hydraulic oil then flows from port (7) to port (5) and back to the tank. This allows the boom to lower.

Boom Hold

|

|

|

|

|

|

| Illustration 5 | g00795503 |

|

(4) Joystick (5) Inlet port (6) Sealing face (7) Outlet port to head end of boom cylinder (8) Spool 1 (9) Chamber |

|

When joystick (4) is moved to the NEUTRAL position, the boom cylinder is held in the raised position. This allows spool (8) to move upward due to spring force in chamber (9). Spool (8) will then seal against sealing face (6). Spool (8) prevents oil from leaking from port (7) to port (5) .

Relief Operation of the Cylinder Head End

|

|

|

|

|

|

| Illustration 6 | g00795592 |

|

(1) Main control valve (2) Boom lowering control valve (3) Boom cylinder (4) Joystick (5) Inlet port (7) Outlet port to head end of boom cylinder (8) Spool 1 (9) Chamber (10) Passage to drain (11) Piston (12) Inlet port for pilot oil (13) Chamber (14) Spool 2 (15) Relief valve |

|

When the boom is pushed downward by an outside force, the oil pressure in port (7) increases. The oil pressure is sensed at relief valve (15). When oil pressure overcomes the relief valve setting, the relief valve allows oil to fill chamber (16). The oil pressure in chamber (16) moves spool (14) downward. Oil then flows from chamber (9) to passage (10). This will allow spool (8) to open. Hydraulic oil will then flow from port (7) to port (5) and back to the tank. This lowers the hydraulic oil pressure until the hydraulic oil pressure is lower than the relief valve setting.