Sensors provide information to the controller about changing conditions. Some types of information are listed: speed, temperature and fluid level. The sensor signal changes in a proportional manner. This change will represent the changing condition. The controller will recognize the following types of sensor signals:

Frequency – The sensor will produce an AC signal (sine wave or square wave) that varies in frequency (Hz) as the condition changes.

Pulse Width Modulated – The sensor produces a digital signal (PWM) that varies the duty cycle as the condition changes. The frequency of the signal will remain constant.

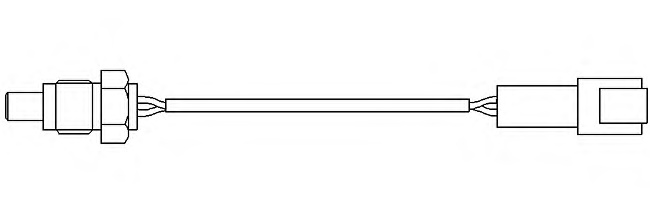

Engine Speed Sensor

|

|

|

|

|

|

| Illustration 1 | g00685339 |

|

Engine Speed Sensor |

|

The engine speed sensor is located on the flywheel housing. An AC voltage is produced as the gear teeth of the flywheel pass the tip of the sensor. The frequency of the voltage is proportional to the speed of the gear teeth as the teeth pass the tip of the sensor. The controller uses this signal to make decisions for the hydraulic pump and the engine.

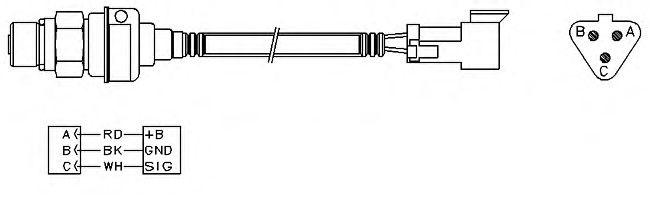

Pressure Sensor

|

|

|

|

|

|

| Illustration 2 | g00685436 |

Pump Discharge 1 (Drive) and Pump Discharge 2 (Idle)

These sensors send a signal to the controller. The controller will use the signal to modify the following items:

- Adjusting the horsepower

- Changing the travel speed

- Determining light load and “AEC” level 1