This calibration procedure is used in order to record the correction data of the proportional solenoid valve for the tool control. This calibration should be done at the following times: replacement of the NFC solenoid valve, replacement of the ECM, flash new software and adjustments to the horsepower controls on the pump.

Before this procedure is performed , ensure that the following requirements are met:

- Verify that the governor actuator is properly calibrated. If necessary, see Testing and Adjusting, “Governor Actuator – Calibrate” for the Tool Control System.

- Verify that the pilot pressure is set to the proper specification that is found in Testing and Adjusting, “Relief Valve (Pilot) – Test and Adjust” for the machine.

- Verify that the main relief valve is set to the proper specification that is found in Testing and Adjusting, “Relief Valve (Main) – Test and Adjust” for the machine.

- Verify that the proportional reducing valve (power shift) is properly calibrated. If necessary, see Testing and Adjusting, “Proportional Reducing Valve – Calibrate (Power Shift)” for the Engine and Pump Control System.

There are two methods for calibrating the proportional solenoid valve for negative flow control. One method uses a flow meter and a pressure gauge. This method is more accurate. The other method uses only a pressure gauge. This method is less accurate. Both methods are described below.

Note: The less accurate method which uses only a pressure gauge is used only when a flow meter is not available.

The device for activation for the work tool is the right foot pedal (1) and the left foot pedal (2) .

|

|

|

|

|

|

| Illustration 1 | g00690414 |

|

(1) Right foot pedal for the work tool. (2) Left foot pedal for the work tool . |

|

Calibration With Pressure Gauge and Flow Meter

- Position the machine on level ground and stop the engine.

Note: When additional safety is needed on machines that are equipped with a swing brake solenoid, disconnect the swing brake solenoid so that the swing brake remains engaged.

- Release the pressure in the hydraulic system. Refer to Testing and Adjusting, “Hydraulic System Pressure – Release” for the machine.

- Install a 300 L (80 US gal) flow meter in the hydraulic line to the tool.

Note: Table 1 lists the parts which appear in illustration 2.

Table 1 TOOL CHART FOR FLOW TEST Item Number Part Number Part Description Quantity 10 4C-9910 Flow Meter 1 11 6K-6307 O-ring seal 2 12 8C-9026 Adapter 2 13 7M-8485 O-ring seal 8 14 4C-6482 Nipple 4 9U-5086 Optional Dust Cap 4 15 4C-6481 Coupler 4 9U-5084 Optional Dust Plug 4 16 4C-8767 Coupling 4 17 5P-1010 Sleeve 4 18 5P-0201 XT-5 Hose 3.5 m (12 ft)

2 19 8T-4194 Bolt 4 20 8T-4223 Hard Washer 2 21 1P-5767 Half Flange 4 22 1U-8293 Adapter 2 23 1P-3704 Rectangular Seal 2 28 6V-4143 Coupler 2 29 6V-3014 Hose 1 30 6V-3989 Nipple 1 31 8T-0861 Pressure Gauge 1 - Connect one end of hydraulic line (32) for the flow meter to the connection on the left side of the flow meter (input port). Connect the other end of this hydraulic line to the port on the supply side of the stick.

Illustration 2 g00990081 (24) Port on supply line for work tool

(25) Port on return line for work tool

(26) Pump pressure tap

(27) Pump pressure tap

(35) Main pump

Illustration 3 g00990153 (10) Flow meter

(32) Supply line for work tool

(33) Return line for work tool

(34) Load valve for flow meter

- Connect one end of the second hydraulic line (33) for the flow meter to the connection on the top of the flow meter (output port). Connect the other end of this hydraulic line to the port on the return side of the stick.

- Install a 40000 kPa (5800 psi) pressure gauge on pressure tap (26) .

Note: Refer to Illustration 4 for the 320C and the 322C machines.

Note: Refer to Illustration 5 for the 325C machines.

|

|

|

|

|

|

| Illustration 4 | g01000946 |

|

Pump compartment for the 320C and the 322C (26) Pressure tap (idler pump) (27) Pressure tap (drive pump) (37) Pressure tap (power shift) |

|

|

|

|

|

|

|

| Illustration 5 | g01000947 |

|

Pump compartment for the 325C (26) Pressure tap (idler pump) (27) Pressure tap (drive pump) (37) Pressure tap (power shift) |

|

- Place the backup switch in the AUTO position.

- Start the engine.

- Move the engine speed dial to position 10.

- Increase the oil temperature to 50 °C (122 °F).

Two Pump Calibration

- Excavators that are equipped with a System 11 have a one pump/two pump switch. Be sure that the cab switch for one pump/two pump flow (A) is set for the flow of two pumps (C) .

|

|

|

|

|

|

| Illustration 6 | g00994428 |

|

(B) Switch position for one pump flow (C) Switch position for two pump flow |

|

- Be sure that the tool that is selected for use is a work tool that provides two pump flow. The default programming for “TOOL#4” is for two pump operation. Refer to Testing and Adjusting, “Work Tool – Select” for the Tool Control System. If “TOOL#4” has been reprogrammed for one pump flow, select a tool that provides two pump flow.

- Enter service mode. Refer to Testing and Adjusting, “Service Mode – Enter” for the Tool Control System.

- After entering service mode, the above screen should be displayed.

Note: The fourth line will indicate the sales model of the excavator.

|

|

|

|

|

|

| Illustration 7 | g00767964 |

|

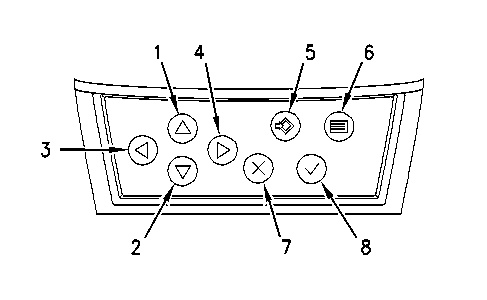

(1) Up key (2) Down key (3) Left Key (4) Right key (5) Set key (6) Menu key (7) Cancel key (8) OK key |

|

|

|

|

|

|

|

| Illustration 8 | g01000769 |

- Press down key (2) in order to highlight line 2. Select “CALIBRATION” with left key (3) or right key (4) . This is shown in illustration 9.

|

|

|

|

|

|

| Illustration 9 | g00694795 |

- Press down key (2) in order to highlight line 3. The calibration device name will appear on line 3. Press the keys for direction in order to scroll through the calibrations that are available. Change the calibration device name to “2PFLOW”. The calibration must be performed at the higher flow rate (“2PFLOW – MAX”), and the calibration must be performed at the lower flow rate (“2PFLOW – MIN”). Refer to Table 2 for the proper flow rate of the machine that is being tested.

Table 2 Flow Rates

Flow rates at

16000 ± 500 kPa (2320 ± 72 psi)One Pump

MAXOne Pump

MINTwo Pump

MAXTwo Pump

MIN320C and 322C 180 ± 3 L (48 ± 0.8 US gal) 120 ± 3 L (32 ± 0.8 US gal) 200 ± 3 L (53 ± 0.8 US gal) 120 ± 3 L (32 ± 0.8 US gal) 325C 200 ± 3 L (53 ± 0.8 US gal) 140 ± 3 L (37 ± 0.8 US gal) 220 ± 3 L (58 ± 0.8 US gal) 140 ± 3 L (37 ± 0.8 US gal)

- Perform the “2PFLOW – MAX” calibration first. In order to change from the “MIN” calibration to the “MAX” calibration, highlight line 3. Press menu key (6) in order to move the portion of line 3 that is highlighted to the right. This is shown in illustration 10. Press left key (3) or right key (4) in order to change the calibration from “MIN” to “MAX”.

|

|

|

|

|

|

| Illustration 10 | g00935143 |