When the main pumps have been serviced or the hydraulic oil has been replaced, remove the air from the hydraulic system. Remove the air from the hydraulic system in the following manner:

|

|

| NOTICE |

|---|

|

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids. Refer to Special Publication, NENG2500, “Caterpillar Tools and Shop Products Guide” for tools and supplies suitable to collect and contain fluids on Caterpillar products. Dispose of all fluids according to local regulations and mandates. |

|

|

|

Personal injury can result from hydraulic oil pressure and hot oil. Hydraulic oil pressure can remain in the hydraulic system after the engine has been stopped. Serious injury can be caused if this pressure is not released before any service is done on the hydraulic system. Make sure all of the work tools have been lowered to the ground, and the oil is cool before removing any components or lines. Remove the oil filler cap only when the engine is stopped, and the filler cap is cool enough to touch with your bare hand. |

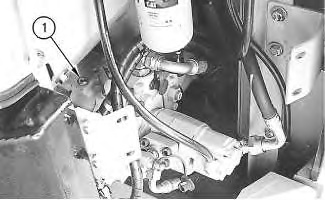

- While the engine is stopped, remove vent plug (1) from the top of the main pump housing.

|

|

|

|

|

|

| Illustration 1 | g00858104 |

|

Pump compartment (1) Vent plug |

|

- Fill the main pumps with oil.

- Inspect the O-Ring seal on vent plug (1). If the seal is damaged, replace the seal.

- Install vent plug (1) in the pump housing.

- Start the engine.

|

|

| NOTICE |

|---|

|

To avoid system damage, make sure that the hydraulic pump is properly filled with hydraulic oil before start-up. |

|

|

- Place the engine at low idle position. Raise the boom and hold the boom in this position.

- Stop the engine and slowly lower the boom until the bucket is on the ground. This pressurizes the hydraulic tank.

- Slowly loosen vent plug (1) until oil begins to flow from the opening.

- Tighten the vent plug to the specified torque.