|

|

|

|

|

|

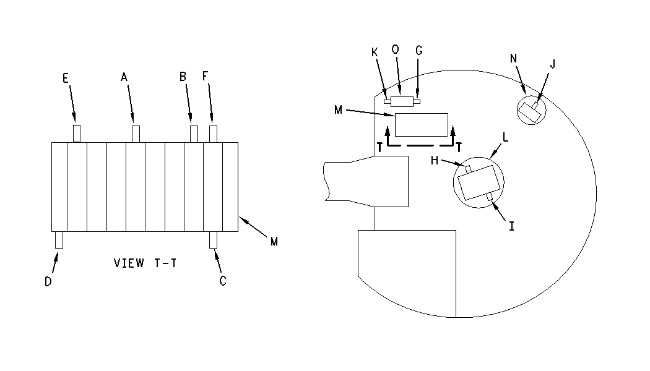

| Illustration 1 | g00858128 |

|

Relief valve locations (A) Main relief valve (B) Boom cylinder line (rod end) (C) Boom cylinder line (head end) (D) Stick cylinder line (rod end) (E) Stick cylinder line (head end) (F) Bucket cylinder line (head end) (G) Blade cylinder line (head end) (H) Swing (right) (I) Swing (left) (J) Pilot relief valve (K) Blade control valve relief valve (L) Swing motor (M) Main control valve (N) Pilot filter (O) Blade control valve |

|

| Relief Valve | Specifications | Torque for Locknut | CHS Inspection Step Number (1) | ||

|---|---|---|---|---|---|

| New Rebuilt (2) |

Service Limit (3) | ||||

| (A) Main relief valve | Implement | 27500 ± 500 kPa (4000 ± 75 psi) | 25550 to 28000 kPa (3715 to 4075 psi) | 65 ± 5 N·m (50 ± 5 lb ft) | 66 |

| Travel | 31400 ± 500 kPa (4550 ± 75 psi) | 29500 to 31900 kPa (4265 to 4625 psi) | 85 ± 5 N·m (60 ± 5 lb ft) | ||

| (B) Boom cylinder line (head end) | 3100 ± 1500 kPa (4500 ± 215 psi) | 27950 to 32370 kPa (4070 to 4715 psi) | 30 ± 2 N·m (20 ± 1 lb ft) | 138 | |

| (C) Boom cylinder line (rod end) | |||||

| (D) Stick cylinder line (head end) | 136 | ||||

| (E) Stick cylinder line (rod end) | 134 | ||||

| (F) Bucket cylinder line (head end) | 140 | ||||

| (H) Swing relief pressure (right) | 24000 ± 1000 kPa (3500 ± 150 psi) | 22000 to 25000 kPa (3200 to 3600 psi) | 40 ± 5 N·m (30 ± 5 lb ft) | 147 | |

| (I) Swing relief pressure (left) | 145 | ||||

| (J) Pilot relief valve | 4100 to 4300 kPa (595 to 625 psi) | 50 ± 5 N·m (35 ± 5 lb ft) | 50 | ||

| (K) Main relief valve (blade) | 20500 ± 1500 kPa (3000 ± 215 psi) | 17650 to 22070 kPa (2570 to 3215 psi) | 30 ± 2 N·m (20 ± 1 lb ft) | ||

| (G) Blade cylinder line (head end) | 24500 ± 1500 kPa (3550 ± 215 psi) | 21550 to 25970 kPa (3100 to 3750 psi) | |||

| ( 1 ) | Custom Hydraulic Service (CHS) is a preventive maintenance program for the machine hydraulic system. CHS is also a valuable part of any Customer Support Agreement. Refer to Custom Hydraulic Service, REHS1780. |

| ( 2 ) | A New specification is the performance that can be expected for a new machine. A Rebuild specification is the performance that can be expected after rebuilding the components of a system. |

| ( 3 ) | Performance beyond Service Limit specifications is an indication of these problems: improper adjustment , wear , damage of relief valves and damage of pumps. |

| Cycle Times (seconds) | ||

|---|---|---|

| Function | Factory | CHS Inspection Step Number (1) |

| Boom EXTEND | 3.6 ± 0.5 | 192 |

| Boom RETRACT | 2.9 ± 0.5 | |

| Stick EXTEND | 3.0 ± 0.5 | 195 |

| Stick RETRACT | 2.3 ± 0.5 | 197 |

| Bucket EXTEND | 4.2 ± 0.5 | 199 |

| Bucket RETRACT | 2.8 ± 0.5 | 201 |

| Blade EXTEND | 1.0 ± 0.5 | |

| Blade RETRACT | 0.8 ± 0.5 | |

| Swing LEFT (180°) | 3.8 (2) | 208 |

| Swing RIGHT (180°) | ||

| Overswing LEFT | 650 mm (25.6 inch) (2) | 209 |

| Overswing RIGHT | ||

| Forward travel HIGH (Left and Right) (3 revolutions) |

13.5 (2) | 217 (left) 218 (right) |

| Reverse travel HIGH (Left and Right) (3 revolutions) |

||

| Forward travel LOW (Left and Right) (3 revolutions) |

20.4 (2) | |

| Reverse travel LOW (Left and Right) (3 revolutions) |

||

| ( 1 ) | Custom Hydraulic Service (CHS) is a preventive maintenance program for the machine hydraulic system. CHS is also a valuable part of any Customer Support Agreement. Refer to Custom Hydraulic Service, REHS1780. |

| ( 2 ) | Maximum |

| Cylinder Drift (Empty Bucket) | |||

|---|---|---|---|

| Function | Factory | CHS Inspection Step Number (1) | |

| Boom cylinder (2) | 6.0 mm (0.24 inch) | 228 | |

| Stick cylinder (2) | 10.0 mm (0.39 inch) | ||

| Bucket cylinder (2) | 10.0 mm (0.39 inch) | 237 | |

| Blade cylinder | 9.0 mm (0.35 inch) | ||

| ( 1 ) | Custom Hydraulic Service (CHS) is a preventive maintenance program for the machine hydraulic system. CHS is also a valuable part of any Customer Support Agreement. Refer to Custom Hydraulic Service, REHS1780. |

| ( 2 ) | Cylinder drift with the engine stopped for five minutes |

| Required Tools | ||

|---|---|---|

| Part Number | Description | Qty |

| 9U-7400 | Multitach Tool Group | 1 |

| 4C-6500 | Digital Thermometer | 1 |

| Relief Valves | Pressure change With One Turn Of Adjustment Screw |

|---|---|

| Main implement valves | 21600 kPa (3150 psi) |

| Main travel valve | 28400 kPa (4100 psi) |

| Line relief valve | 17700 kPa (2550 psi) |

| Swing relief valve | 9700 kPa (1400 psi) |

| Blade control valve relief valve | 15700 kPa (2300 psi) |

| Relief valve for blade cylinder | 17700 kPa (2550 psi) |

| Pilot relief valve | 625 kPa (90 psi) |

Note: Pressure values in Table 5 are approximate values. Use a pressure gauge for adjustment.

Note: Normal operations of the engine and pumps are necessary for the pressure adjustments. If the results of the pressure adjustment are not correct, then the engine and the pump characteristic curve needs to be checked. Slow output flow from the pump is an indication of air in the hydraulic system. Make sure that no air is present in the hydraulic system. Refer to Testing And Adjusting, “Main Hydraulic Pump Air – Purge”.