Often when problems with the charging system are being investigated, the alternator is not the problem. If a low battery condition is present, test the batteries first. See Special Instruction, SEHS7633, “Battery Test Procedure” for more information. If the engine cranks slowly, then test the starting system. See Service Magazine, SEPD0020, “Testing The Starter On The Engine” for more information. If a warning indicator for the charging system is ON, see Service Magazine, SEBD1751, “Difference Between Alternator Indicator In Electronic Monitoring System (EMS) And Low Voltage Indicator In Operating Monitoring System (OMS)”. When a problem with the charging system is suspected, then complete the testing that is outlined in this Special Instruction.

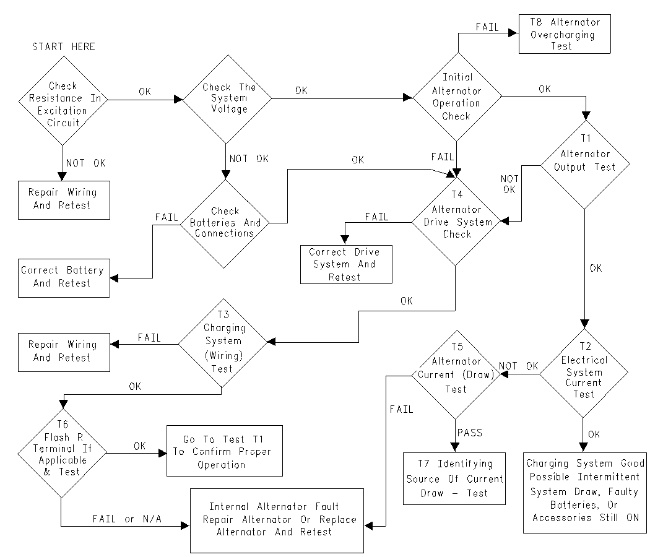

See “Initial Troubleshooting Procedure” in order to begin troubleshooting. The procedures in this Special Instruction are designed to guide you to the problem with as little testing as possible. In most cases, you will only use a few of the tests to diagnose a problem. The tests are labeled as T1 – T8 for easy reference. A descriptive title for each test is included as well.

Initial Troubleshooting Procedure

- CHECK THE RESISTANCE IN THE EXCITATION CIRCUIT. This step is only for alternators with external excitation when the terminal for excitation is labeled: “1”, “REG” and “D+”. See “Alternator Specifications” if the method of excitation is unknown. Go to Step 3 if your alternator is self-excited. Proceed to Step 2 if the excitation terminal of the alternator has the label “IG”.

- Turn the key start switch to the ON position.

- Verify voltage at the excitation terminal. Connect the red lead from a multimeter to the excitation terminal. Connect the black lead to a ground source (alternator case ground).

- Read the voltage that is shown on the multimeter.

Expected Result: The voltage reads at least .2 volts.

Results:

- YES – The voltage reads .2 volts or more. The excitation circuit is correct. Proceed to Step 3.

- NO – The voltage is less than .2 volts. There is a failure in the wiring harness to the alternator or there is a poor electrical connection. Correct the problem and operate the machine. Watch for a recurrence of the problem.

- CHECK THE RESISTANCE IN THE EXCITATION CIRCUIT (CONTINUED). This step is only for alternators with external excitation when the terminal for excitation is labeled: “IG”. See “Alternator Specifications” if the method of excitation is unknown. Go to Step 3 if your alternator is self-excited.

- Turn the key start switch to the ON position.

- Verify voltage at the excitation terminal. Connect the red lead from a multimeter to the excitation terminal. Connect the black lead to a ground source. The case of the alternator can be used as a good source of ground.

Note: For Denso G3B, K3A, and L3A alternators, Insert a 7X-1710 Multimeter Probe Group into the rear of the middle wire in the connector. See figure 1 below. Insert the probe (spoon lead) between the black seal that surrounds the wire and the outer shell of the connector. Do not insert the probe between the wire insulation and the black seal. This terminal (IG) is the terminal for excitation.

- Read the voltage that is shown on the multimeter.

Expected Result: The voltage is within .5 volts of battery voltage.

Results:

- YES – The voltage reads battery voltage. The excitation circuit is correct. Proceed to Step 3.

- NO – The voltage is more than .5 volts less than battery voltage. There is a failure in the wiring harness to the alternator or there is a poor electrical connection. Correct the problem and operate the machine. Watch for a recurrence of the problem.

Illustration 1 g00496660 Special Technique Using A Wire Probe On The Denso Alternator

- CHECK THE SYSTEM VOLTAGE.

- Before starting the machine, connect a voltmeter between the “B+” terminal and the case of the alternator. Turn OFF all electrical loads.

- Turn the key to the ON position but do not start the engine.

Expected Result: This voltage should be system voltage.

Results:

- YES – The voltage is system voltage. Go to Step 4

- NO – The voltage is less than system voltage. Verify that the batteries are good and verify that battery connections are good. Go to “”T4 Alternator Drive System – Check”” if the batteries are good.

- INITIAL CHECK OF THE OPERATION OF THE ALTERNATOR.

- The voltmeter remains connected in the configuration from Step 3.

- Start the machine. Set the throttle to at least 75 percent. Read the voltage on the voltmeter.

Expected Result: The voltage is higher than the voltage that was recorded in the previous Step 3.

Results:

- YES – The voltage is higher than the voltage observed in the previous Step 3. The voltage is also lower than the maximum voltage that is listed in the specifications for the alternator. The alternator is partially charging. See the following diagnostic flow chart for reference in continued testing. Proceed to “”T1 Alternator Output – Test””.

- YES – The voltage is higher than the voltage observed in the previous Step 3. The voltage is also higher than the maximum voltage that is listed in the specifications for the alternator. The alternator is over charging. Proceed to “”T8 Alternator Overcharging – Test””.

- NO – The voltage is not higher than the voltage observed in Step 3. Proceed to “”T4 Alternator Drive System – Check””.

Note: Severely discharged batteries can cause low system voltage. Severely discharged batteries can occur even while the engine is running above idle, and the alternator is working properly. Proper low engine idle is also important. Most of the alternators in Caterpillar applications are self-excited. These alternators must exceed a turn-on speed before charging will begin. Alternator output can be low at idle.

|

|

|

|

|

|

| Illustration 2 | g00508188 |

T1 Alternator Output – Test

- Ensure that the batteries are NOT fully charged.

- Fully charged batteries have open circuit voltage above 12.5 V on 12 V systems or 25 V on 24 V systems.

- If the batteries are fully charged, then crank the engine for 30 seconds. This action reduces the battery voltage. Operate the lights for 10 minutes while the engine is off as an alternative.

- Connect the 9U-5795 Current Probe to a DMM (digital multimeter) or use a 225-8266 Ammeter Tool Gp . The multimeter must have a peak hold feature. Clamp the probe around alternator output wire “B+”. Before clamping the probe around the wire, ensure that the probe is “zeroed” .

- Set the digital multimeter to “peak hold” or “max mode” on the “mV” scale.

- Turn on all electrical accessories: lights, air conditioning and radio.

- Start the machine, and immediately set the throttle to at least 75 percent. The peak current will appear on the voltmeter in “peak hold” or “max” mode.

Expected Result: This current reading should be at least 90 percent of the specified peak output.

Results:

- OK – The current is at least 90 percent of the specified peak output. Go to “”T2a – Undesired Electrical System Current – Test (For Machines Equipped With A Main Disconnect Switch”” OR “”T2b – Undesired Electrical System Current – Test (For Any Machine)””.

- NOT OK – The current is less than 90 percent of the specified peak output. Go to “”T4 Alternator Drive System – Check””.

T2a – Undesired Electrical System Current – Test (For Machines Equipped With A Main Disconnect Switch)

- Turn off all of the accessories. Turn the keyswitch to the OFF position.

- Clamp a 9U-5795 Current Probe or 225-8266 Ammeter Tool Gp around the main ground cable. Clamp the tool with the positive side away from the battery. Reset the probe (zero) before clamping the probe around the wire. Read the current.

Expected Result: The current is below 2 A.

Results:

- YES – The current is below 2 A. Continue to Step 3.

- NO – The current is above 2 A. There is a current draw in the system. Go to “”T5 Alternator Current – Test””.

- Turn the disconnect switch to the ON position. Connect a multimeter across the disconnect switch terminals. Connect the red lead to the terminal on the frame side. Connect the black lead to the terminal on the battery side. Use the 10A connections in order to avoid damage.

- Turn off the disconnect switch and read the current.

Expected Result: The current is below .050 A (50 mA).

Note: The standard acceptable current draw is 50 mA. A current draw above 50 mA usually indicates a problem. However, some large machines with multiple electronic control modules have a higher acceptable limit. Contact a Caterpillar dealer for more information.

Results:

- YES – The current is below 0.050 A. The charging system is currently good. The fault is possibly an intermittent draw in the system. The batteries may be faulty. Check that NO accessories were ON during the test.

- NO – The current is above 0.050 A. There is a draw in the system. Go to “”T5 Alternator Current – Test””.

T2b – Undesired Electrical System Current – Test (For Any Machine)

- Turn off all accessories. Turn the keyswitch to the OFF position.

- Clamp a 9U-5795 Current Probe or 225-8266 Ammeter Tool Gp around the main ground cable. Clamp the tool with the positive side away from the battery. Reset the probe (zero) before clamping around the wire. Read the current.

Expected Result: The current is below 2 A.

Results:

- YES – The current is below 2 A. Continue to Step 3.

- NO – The current is above 2 A. There is a current draw in the system. Go to “”T5 Alternator Current – Test””.

- Remove the ground cable from the battery terminal. For systems with 4 batteries, or 12 V systems with 2 batteries, disconnect the ground cables from both negative batteries.

- Connect a multimeter between the disconnected battery ground cable and one of the negative battery terminals. Connect the red positive lead of the multimeter to the cable. The negative lead should be connected to the battery terminal. Use the 10A connections in order to avoid damage.

Expected Result: The current is below .050 A (50 mA).

Note: The standard acceptable current draw is 50 mA. A current draw above 50 mA usually indicates a problem. However, some large machines with multiple electronic control modules have a higher acceptable limit. Contact a Caterpillar dealer for more information.

Results:

- YES – The current is below 0.050 A. The charging system is currently good. The fault is possibly an intermittent draw in the system. The batteries may be faulty. Check that NO accessories were ON during the test.

- NO – The current is above 0.050 A. There is a draw in the system. Go to “”T5 Alternator Current – Test””.

Note: The following alternators have a connector for a regulator: 6T-1193 , 6T-1194 , 6T-1195 , 6T-1196 , 9G-6079 and 9G-6081 . Disconnect the regulator connector from the alternator. Recheck the current that was found in the previous Step. If the current is below 0.050 A (50 mA), the regulator is faulty.

T3 Charging System – Test

- Verify that the alternator B+ terminal nut is tight and verify that the wire has a good connection to the B+ terminal.

- Many Caterpillar machines are equipped with a connector for the 6V-2150 Starting/Charging Analyzer . Use of this tester replaces the testing below. See Systems Operation, SENR2947, “Starting and Charging Systems”.

- Start the engine and set the throttle to at least 75 percent. Turn ON all electrical accessories for all test steps below. Allow the engine to run for at least 3 minutes before continuing to Step 4. The following table will assist in making calculations during this test.

Table 1 Test Step Voltage Reading Voltage should be below this for 12 V system Voltage should be below this for 24 V system 4 5 4 minus 5 = 1.0 V 2.0 V 6 7 6 minus 7 = 0.5 V 1.0 V 8 0.5 V 1.0 V

- Measure the voltage between the alternator B+ terminal and the alternator case ground.

- Measure the voltage across the battery. Put the red lead on the + battery terminal, and put the black lead on the negative battery terminal. Step 5 should be completed as quickly as possible after Step 4.

Expected Result: The voltage is less than the voltage or the voltage is equal to the voltage that was recorded in Step 4 for a 12 V system. However, the voltage is within 1 V. On 24 V systems, the voltage is within 2 V.

Results:

- YES – If the voltage in Step 4 is not more than 1 V for 12 V systems (2 V for 24 V systems) higher than the voltage in Step 5, this test is complete and the related wiring is correct at this time. Replace the alternator or disassemble the alternator and repair.

- NO – If the voltage in Step 4 is more than 1 V for 12 V systems (2 V for 24 V systems) higher than the voltage in Step 5, there is high circuit resistance: corrosion, loose connections and damaged wiring. Continue to Step 6.

- Check the voltage between the machine frame and the alternator B+ terminal. Record the voltage.

- Check the voltage between the machine frame and the + battery post. Step 7 should be completed as quickly as possible after Step 6.

Expected Result: The voltage difference between Step 6 and Step 7 does not exceed 1 V on 24 V systems or 0.5 V on 12 V systems.

Results:

- YES – The voltage difference does not exceed the tolerance. The charging circuit is good. Go to Step 8.

- NO – The voltage difference exceeds the tolerance. There is high resistance in the charging circuit: loose cables, corroded cables, damaged cables and faulty circuit breaker. Correct the problem and retest the system.

- Check the voltage between the negative battery post and the alternator case ground.

Expected Result: The voltage does not exceed 1 V on 24 V systems or 0.5 V on 12 V systems.

Results:

- YES – The voltage difference does not exceed the tolerance. The ground circuit is good. There is an internal problem with the alternator. Go to “”T6 Residual Magnetism Restoration””.

- NO – The voltage difference exceeds the tolerance. There is high resistance in the ground circuit: loose cables, corroded cables, loose alternator mounting and poor engine ground. Correct the problem and retest the system.

T4 Alternator Drive System – Check

- Check the condition of the alternator drive belt. If the drive belt is oily, clean the pulleys. Replace the drive belt, and retest the system. If the drive belt is wet, dry the belt and retest the system. If the drive belt is worn, replace the belt and retest the system.

- Check the tension of the alternator drive belt. If the tension is off, adjust the tension.

- Check the nut on the alternator pulley. If the nut is loose, tighten the nut and retest the system.

- If all of the previous steps find no problems, go to “”T3 Charging System – Test””.

T5 Alternator Current – Test

- Turn the keyswitch to the OFF position.

- Connect the 9U-5795 Current Probe to a DMM (digital multimeter) or use a 225-8266 Ammeter Tool Gp . Clamp the probe around the alternator output wire (“B+”). Before clamping the probe around the wire, ensure that the probe is “zeroed” .

- Read the current.

Expected Result: The current is under 2 A.

Results:

- YES – The current is under 2 A. Continue to Step 4.

- NO – The current is over 2 A. There is an internal problem with the alternator. Go to “”T6 Residual Magnetism Restoration””.

- Disconnect the B+ terminal wire from the alternator. Connect the red lead of the multimeter to the wire that was disconnected. Connect the black lead of the multimeter to the B+ terminal of the alternator. Set the multimeter on the 10 amp scale. Read the current.

Expected Result: The current is under 0.015 A.

Results:

- YES – The current is under 0.015 A. The alternator is operating correctly. There is a current draw on the machine. Go to “”T7 Identifying Source Of Current Draw – Test””.

- NO – The current is greater than 0.015 A. There is an internal problem with the alternator. Go to “”T6 Residual Magnetism Restoration””.

T6 Residual Magnetism Restoration

This test is only for self-excited alternators. See Service Magazine, SEBD1672 July 1986, “Brushless Alternators May Not Charge In Certain Conditions” for additional information.

- Start the engine and set the throttle to at least 75 percent.

- Connect a voltmeter between the “B+” terminal and the alternator case ground.

- If a wire is connected, disconnect the wire from the “R” terminal.

Expected Result: The voltage remains unchanged.

Results:

- YES – The voltage stays the same. Continue to Step 4.

- NO – The voltage rises and the alternator begins charging. The wire to the “R” terminal is shorted. Repair the wiring or replace the wiring. Go to “Initial Troubleshooting Procedure” and retest the system.

- Connect one end of a jumper wire to the “B+” terminal of the alternator.

- Connect the other end of the jumper wire to the “R” terminal (“D+” terminal for Bosch) of the alternator for 2 seconds.

Expected Result: The voltage output rises on the “B+” terminal.

Results:

- OK – The voltage output rises. The alternator is now charging. Go to “Initial Troubleshooting Procedure” and retest the system.

- NOT OK – The voltage output does not rise. Proceed to Step 6, if the alternator has a wire that is connected to the “I” terminal. Disassemble the alternator and repair the alternator. Replace the alternator if the alternator cannot be repaired.

- Remove the wire that is connected to the “I” terminal. Check for a rise in voltage on the “B+” terminal.

Expected Result: The voltage rises.

Results:

- YES – The voltage rises. There is a short in the wiring to the terminal. Repair the wiring or replace the wiring. Go to “Initial Troubleshooting Procedure” and retest the system.

- NOT OK – The voltage output does not rise. Disassemble the alternator and repair the alternator. Replace the alternator if the alternator cannot be repaired.

T7 Identifying Source Of Current Draw – Test

- Make sure that every electrical component is turned OFF. Make sure that the keyswitch is turned OFF. Make sure that the dome lights are OFF.

- Clamp a 9U-5795 Current Probe or 225-8266 Ammeter Tool Gp around the main ground cable. Clamp the tool with the positive side away from the battery. Reset the probe (zero) before clamping the probe around the wire. Use the current probe if the draw is above approximately 2 A. Use the Ammeter if the draw is below approximately 2 A.

- Monitor the current and remove fuses and breakers one at a time. Check the current after each fuse (breaker) is removed. After removing a fuse (breaker) and observing the current, reinstall the fuse (breaker). Start with the main fuses (circuit breakers) first, and proceed to smaller circuits.

- If a removal of a fuse causes the current to drop, then the problem is in that circuit.

- Check if any components on the circuit are ON.

- If everything is OFF, disconnect electrical components on that circuit one at a time and monitor current.

- After all of the components in that circuit have been disconnected, check the current. If the problem still exists, then check the wiring for corrosion or shorts to ground.

Note: The standard acceptable current draw is 50 mA. A current draw above 50 mA usually indicates a problem. However, some large machines with multiple electronic control modules have a higher acceptable limit. Contact a Caterpillar dealer for more information.

T8a – Alternator Overcharging – Test

This test should be used on alternators that have an “IG”, a “S” or some other sensing terminal.

- Clean the connection and tighten the connection to the wiring terminal on the alternator.

- Verify that the alternator B+ terminal nut is tight and verify that the wire has a good connection to the “B+” terminal.

- Many Caterpillar machines are equipped with a connector for the 6V-2150 Starting/Charging Analyzer . See Systems Operation, SENR2947, “Starting and Charging Systems”. Use of this analyzer replaces the testing below through Step 8. Therefore, if the testing is good, go to Step 9. If the analyzer finds a problem, correct the problem and retest the system. Go to “Initial Troubleshooting Procedure”.

- Start the engine and set the throttle to at least 75 percent. Turn ON all electrical accessories for all test steps below. Allow the engine to run for at least 3 minutes before continuing to Step 5. The following table will assist in making calculations during this test.

Table 2 Test Step Voltage Reading Voltage should be below this for 12 V system Voltage should be below this for 24 V system 5 6 5 minus 6 = 1.0 V 2.0 V 7 8 7 minus 8 = 0.5 V 1.0 V

- Measure the voltage between the “B+” terminal of the alternator and the case of the alternator.

- Measure the voltage across the battery. Put the red lead on the + battery terminal, and put the black lead on the negative battery terminal. Step 6 should be completed as quickly as possible after Step 5.

Expected Result: The voltage is within 1 V of the voltage that is recorded in Step 5 for 12 V systems. The voltage is within 2 V for 24 V systems.

Results:

- YES – If the voltage in Step 5 is not more than 1 V for 12 V systems (2 V for 24 V systems) higher than the voltage in Step 6, this step is complete and the related wiring is correct at this time. Go to Step 9.

- NO – If the voltage in Step 5 is more than 1 V for 12 V systems (2 V for 24 V systems) higher than the voltage in Step 6, there is high circuit resistance: corrosion, loose connections and damaged wiring. Go to Step 7.

- Check the voltage between the machine frame and the alternator B+ terminal. Record the voltage.

- Check the voltage between the machine frame and the + battery post. Step 8 should be completed as quickly as possible after Step 7.

Expected Result: The voltage difference between Step 7 and Step 8 does not exceed 1 V on 24 V systems or 0.5 V on 12 V systems.

Results:

- YES – The voltage difference does not exceed the tolerance. The charging circuit is good. Go to Step 9.

- NO – The voltage difference exceeds the tolerance. There is high resistance in the charging circuit: loose cables, corroded cables, damaged cables, faulty circuit breaker and faulty main relay. Correct the problem. Go to “Initial Troubleshooting Procedure” and retest the system.

- Start the engine and set the throttle to at least 75 percent. Turn OFF all of the accessories.

- Measure the voltage between the sense terminal and the case of the alternator.

Expected Result: The voltage at the sense terminal is above the specification.

Results:

- YES – The voltage is over specification. There is an internal malfunction in the alternator. See the appropriate service manual for the alternator in order to test the internal components and connections.

- NO – The voltage is below that found in the initial tests (B+ to alternator case). The sense circuit in the machine has high resistance. Correct the problem and retest the system . Go to “Initial Troubleshooting Procedure”.

|

|

|

|

|

|

| Illustration 3 | g00496660 |

|

Special Technique Using A Wire Probe For The Denso Alternator |

|

Note: The following information is used only for the Denso G3B, K3A, and L3A alternators: Insert a 7X-1710 Multimeter Probe Group into the rear of the middle wire in the connector. See figure 3. Insert the probe (spoon lead) between the black seal that surrounds the wire and the outer shell of the connector. Do not insert the probe between the wire insulation and the black seal. This terminal (“IG”) is the terminal for excitation.

T8b – Alternator Overcharging – Test (Continued)

This test is used for alternators that do not have an “IG”, “S” or some other sense terminal.

- Clean the connection and tighten the connection to the wiring terminal on the alternator.

- Verify that the nut on the “B+” terminal of the alternator is tight. Verify that the wire has a good connection to the “B+” terminal.

- Many Caterpillar machines are equipped with a connector for the 6V-2150 Starting/Charging Analyzer . See Systems Operation, SENR2947, “Starting and Charging Systems”. Use of this analyzer replaces the testing below. If the analyzer finds a problem, correct the problem and retest the system. Go to “Initial Troubleshooting Procedure”.

- Run the engine at 75 percent. Turn ON all electrical accessories for all test steps below. Allow the engine to run for at least 3 minutes before continuing to Step 5. The following table describes the measurements that are taken during this test.

Table 3 Test Step Voltage Reading Voltage should be below this for 12 V system Voltage should be below this for 24 V system 5 6 5 minus 6 = 1.0 V 2.0 V 7 8 7 minus 8 = 0.5 V 1.0 V

- Measure the voltage between the “B+” terminal of the alternator and the case of the alternator.

- Measure the voltage across the battery. Put the red lead on the + battery terminal, and put the black lead on the negative battery terminal. Step 6 should be completed as quickly as possible after Step 5.

Expected Result: The voltage is within 1 V of the voltage that was recorded in Step 5 for 12 V systems. The voltage is within 2 V for 24 V systems.

Results:

- YES – If the voltage in Step 5 is not more than 1 V for 12 V systems (2 V for 24 V systems) higher than the voltage in Step 6, this step is complete and the related wiring is correct at this time. There is an internal malfunction in the alternator. See the appropriate service manual for the alternator in order to test the internal components and connections.

- NO – If the voltage in Step 5 is more than 1 V for 12 V systems (2 V for 24 V systems) higher than the voltage in Step 6, there is high circuit resistance: corrosion, loose connections and damaged wiring. Go to Step 7.

- Check the voltage between the machine frame and the “B+” terminal of the alternator. Record the voltage.

- Check the voltage between the machine frame and the + battery post. Step 8 should be completed as quickly as possible after Step 7.

Expected Result: The voltage difference between Step 7 and Step 8 does not exceed 1 V on 24 V systems or 0.5 V on 12 V systems.

Results:

- YES – The voltage difference does not exceed the tolerance. The charging circuit is good. There is an internal malfunction in the alternator. See the appropriate service manual for the alternator in order to test the internal components and connections.

- NO – The difference in the voltage exceeds the tolerance. There is high resistance in the charging circuit: loose cables, corroded cables, damaged cables, failed circuit breaker and failed main relay. Correct the problem. Go to “Initial Troubleshooting Procedure” and retest the system.

Specifications For Alternators

| Specifications For Alternators | ||

|---|---|---|

| Peak Current Rating (Amps) | Minimum Peak Current (Amps) | |

| 12 V Alternators | ||

| 8C-5535 | 32 | 28 |

| 7N-4784 , OR-5201 | 40 | 36 |

| 6T-1396 , 7T-2096 , 8C-5908 , OR-3654 | 51 | 46 |

| 9W-2648 , 9W-2949 , 8T-9700 , 105-2811 (IG), OR-4327 (IG), 105-2812 (IG), OR-9273 (IG), 34-3268 , 68-4139 , 3E-7295 (D+), 7T-2876 (D+), 100-8223 | 55 | 49 |

| 7G-7889 | 60 | 54 |

| 8C-5510 (I), OR5200 | 61 | 55 |

| 8N-2268 | 75 | 68 |

| 3E-7892 , OR-3616 | 85 | 77 |

| 105-2813 (IG), OR-9274 (IG), 105-2814 (IG), OR-4328 (IG), 149-2064 (REG), OR-9410 (REG), 9X-0341 (D+) | 90 | 81 |

| 8C-6163 , OR-1699 , 107-2519 | 105 | 95 |

| 167-7816 | 110 | 99 |

| 9X-6796 , 9X-9096 , 121-4134 , 121-4136 , OR-3527 | 115 | 104 |

| 3E-8827 , 121-4135 , 117-1379 (I) | 130 | 117 |

| 152-8746 | 135 | 122 |

| 125-9597 , OR-8332 | 145 | 131 |

| 24 V Alternators | ||

| 2P-1204 , 3Y-8200 | 19 | 17 |

| 2Y-8310 | 21 | 19 |

| 6T-1395 , 7T-2095 , OR-3653 | 33 | 30 |

| 6N-9294 , OR-5217 , OR-3482 | 35 | 32 |

| 5N-5692 , OR-2698 | 45 | 41 |

| 5S-9088 , 100-5047 , 112-5041 , 3E-7578 , OR-5206 , OR-3667 , OR-3668 | 50 | 45 |

| 109-2362 , 9W-3043 , OR-3652 (D+), 112-8032 |

55 | 50 |

| 3E-7772 (IG), OR-9437 (IG), 105-3132 (IG), 4N-3986 , OR-5203 | 60 | 54 |

| 155-7434 , 132-2156 (I), 107-7977 (I), OR-8279 (I) | 70 | 63 |

| 169-4319 , 167-7812 | 75 | 67.5 |

| 107-7976 , 114-2401 , OR-8997 , 3E-7577 , OR-3615 | 75 | 68 |

| 165-5140 | 100 | 90 |

| 9X-7803 , OR-3749 | 100 | 90 |

| Parts-Service Only Discontinued 12 V Alternators | ||

| 6T-1193 | 18 | 16 |

| 7N-6118 , 6N-5460 , 4N-4540 | 40 | 36 |

| 6T-1195 | 42 | 38 |

| 7X-1340 | 45 | 41 |

| 9G-6079 , 6T-1194 | 63 | 57 |

| Parts-Service Only Discontinued 24 V Alternators | ||

| 9G-6081 , 6T-1196 | 40 | 36 |

| D+ – Diode trio output. Alternator requires external excitation. | ||

| REG – Regulator Terminal. Alternator requires external excitation. | ||

| I – Ignition Terminal. Alternator can be externally excited through this terminal. | ||

| IG – Ignition Terminal. System voltage must be supplied to this terminal to turn on the alternator. Some of these alternators use the IG terminal as a sense terminal. | ||