|

|

|

|

|

|

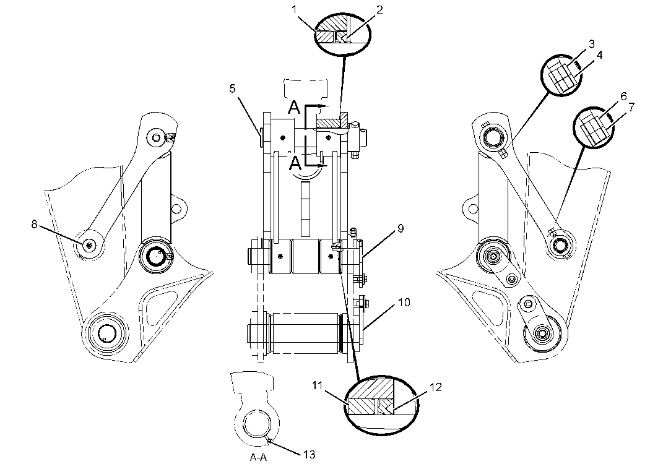

| Illustration 1 | g02544377 |

| Specification for 236-8415 Bucket Linkage Gp , 236-8416 Bucket Linkage Gp, and 282-4566 Bucket Linkage Gp | |||

| Item | Qty | Part | Specification Description |

| – | All bores must be free of paint. Use the 5P-0960 Grease Cartridge in order to lubricate the bores for the pins. | ||

| 1 | 2 | 241-7280 Bushing | Inside diameter is 100.29 ± 0.04 mm (3.950 ± 0.002 inch). Installation depth is 9.5 ± 0.8 mm (0.37 ± 0.03 inch). |

| 2 | 4 | 166-1496 Lip Type Seal | Lubricate the sealing lip of the lip type seals lightly with the lubricant that is being sealed. Install the dust seal so that the lip faces the outside, as shown. Install the lip type seals so that the lip of the lip type seals do not extend beyond the face of the boss. |

| 3 | 1 | 451-2185 Nut | Torque to 530 ± 70 N·m (391 ± 52 lb ft). Position the nut (4) to the distance 0.0 to 1.0 mm (0.00 to 0.04 inch) past the end of the bolt. For locking, tighten the nut (3) against the nut (4) . |

| 4 | 1 | 451-2185 Nut | |

| 5 | 1 | 251-2557 Pin | Diameter is 99.85 ± 0.04 mm (3.931 ± 0.002 inch). |

| 6 | 1 | 451-2184 Nut | Torque to 325 ± 40 N·m (240 ± 30 lb ft). Position the nut (7) to the distance 0.0 to 1.0 mm (0.00 to 0.04 inch) past the end of the bolt. For locking, tighten the nut (6) against the nut (7) . |

| 7 | 1 | 451-2184 Nut | |

| 8 | 1 | 189-3922 Pin | Diameter is 69.850 ± 0.040 mm (2.7500 ± 0.0016 inch). |

| 9 | 1 | 251-2558 Pin As | Diameter is 89.850 ± 0.025 mm (3.5374 ± 0.0010 inch). |

| 10 | 1 | 251-2552 Pin As | Diameter is 99.85 ± 0.04 mm (3.931 ± 0.002 inch). |

| 11 | 2 | 228-5615 Bushing | Bore before assembly is 90.21 ± 0.04 mm (3.552 ± 0.002 inch). Installation depth is 9.5 ± 0.8 mm (0.37 ± 0.03 inch). |

| 12 | 2 | 166-1495 Lip Type Seal | Lubricate the sealing lip of the lip type seals lightly with the lubricant that is being sealed. Install the dust seal so that the lip faces the outside, as shown. Install the lip type seals so that the lip of the lip type seals do not extend beyond the face of the boss. |

| 13 | – | – | During linkage group assembly on the machine, rotate the rod end of the bucket cylinder in order to position the grease fitting away from stick. |