Installation Procedure

|

|

| NOTICE |

|---|

|

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids. Refer to Special Publication, NENG2500, “Caterpillar Tools and Shop Products Guide” for tools and supplies suitable to collect and contain fluids on Caterpillar products. Dispose of all fluids according to local regulations and mandates. |

|

|

Note: Prior to installation, check the condition of the O-ring seals for wear or for damage. If necessary, replace the O-ring seals with new parts.

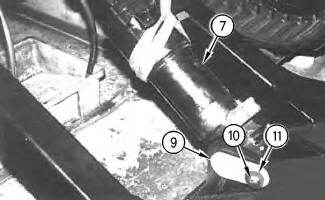

- Attach a suitable lifting device to blade cylinder (7). Lower the head end of the blade cylinder into position on the blade.

- Apply 5P-0960 Molybdenum Grease on pin assembly (9). Install pin assembly (9) with washer (11) and bolt (10). Tighten bolt (10) to a torque of 70 ± 15 N·m (50 ± 11 lb ft).

|

|

|

|

|

|

| Illustration 1 | g00554801 |

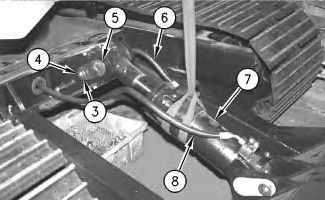

- Apply 5P-0960 Molybdenum Grease on pin assembly (5). Install pin assembly (5) with washer (3) and bolt (4). Tighten bolt (4) to a torque of 70 ± 15 N·m (50 ± 11 lb ft). Remove the lifting device.

- Connect hose assemblies (6) and (8) to the blade cylinder. Tighten the hose assemblies to a torque of 76 ± 4 N·m (56 ± 3 lb ft).

- Lubricate the support pins for the blade cylinder. Refill the hydraulic oil tank with hydraulic oil. Refer to Operation and Maintenance Manual, SEBU7421, “Hydraulic System Oil – Change” for the proper procedure.

- Start the machine, and run the machine at low idle speed. Move the control lever for the blade cylinder so that the cylinder rod extends to the halfway position. Retract the cylinder rod. The cylinder should be cycled in this manner for approximately ten cycles in order to remove the air from the hydraulic system. Recheck the oil level in the hydraulic oil tank.