| Required Tools | ||

|---|---|---|

| Part Number | Description | Qty |

| 8T-0861 | Pressure Gauge ( 60000 kPa (8700 psi)) |

2 |

| 8T-0854 | Pressure Gauge ( 1000 kPa (145 psi)) |

1 |

Note: A temporary setting of the main relief valve pressure is required before any line relief valve pressure setting is adjusted. Refer to Testing and Adjusting, “Relief Valve (Main) – Test and Adjust”.

Preparation

- Position the machine on level ground.

- Stop the engine.

- Release the pressure in the hydraulic system. Refer to Testing and Adjusting, “Hydraulic System Pressure – Release”.

- Set the main relief valve to a higher pressure. Refer to Testing and Adjusting, “Relief Valve (Main) – Test and Adjust”.

- Connect a 60000 kPa (8700 psi) pressure gauge to pressure tap (1). This is used to monitor the line relief valve pressure setting of the stick cylinder.

|

|

|

|

|

|

| Illustration 1 | g00858167 |

|

Pump compartment (1) Pressure tap (right pump delivery pressure) (2) Pressure tap (left pump delivery pressure) |

|

- Connect a 60000 kPa (8700 psi) pressure gauge to pressure tap (2). This is used to monitor the line relief valve pressure setting of the boom cylinders and the bucket cylinder.

|

|

|

|

|

|

| Illustration 2 | g00858357 |

|

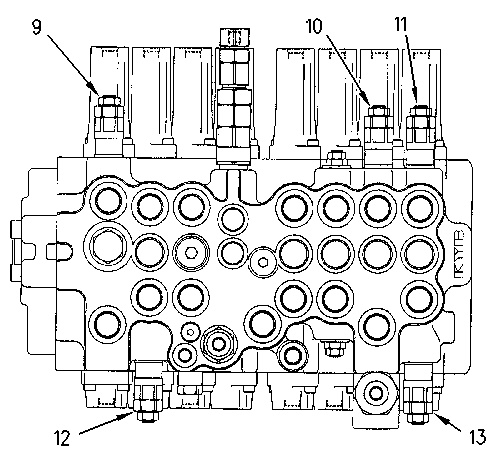

Main control valve (front view) (9) Line relief valve (stick cylinder head end) (10) Line relief valve (boom cylinder rod end) (11) Line relief valve (bucket cylinder head end) (12) Line relief valve (13) Line relief valve |

|

|

|

|

|

|

|

| Illustration 3 | g01028617 |

|

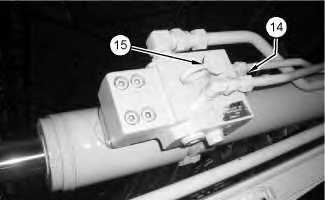

Stick lowering control valve (14) Line relief valve (stick cylinder rod end) (15) Pressure tap (“PR” port on the stick lowering control valve) |

|

|

|

|

|

|

|

| Illustration 4 | g01028613 |

|

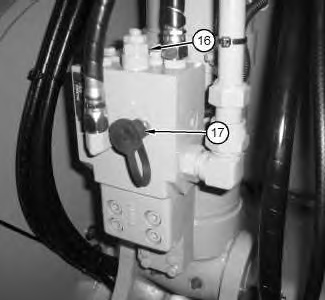

Boom lowering control valve (16) Line relief valve (boom cylinder head end) (17) Pressure tap (“PR” port on the boom lowering control valve) |

|

The following line relief valves are located on top of the main control valves: stick cylinder head end (9), boom cylinder rod end (10) and bucket cylinder head end (11). Line relief valve (14) for the stick cylinder rod end and line relief valve (16) for the boom cylinder head end are located on the lowering control valves.

|

|

|

|

|

|

| Illustration 5 | g01028684 |

|

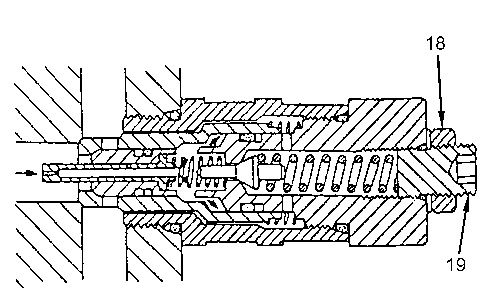

Line relief valve (typical example) (18) Locknut (19) Adjustment screw |

|

Note: Turn adjustment screw (19) clockwise in order to increase the pressure. Turn adjustment screw (19) counterclockwise in order to decrease the pressure.

Note: Always make final pressure adjustment on pressure rise.

Note: Return the main relief valve pressure to the specified setting after testing and adjusting any line relief valve. Refer to Testing And Adjusting, “Relief Valve (Main) – Test and Adjust” for the main relief valve pressure setting.

Adjustment (Boom Cylinders)

Boom Cylinder Head End

- Line relief valve (13) on the main control valve must be set at a higher pressure in order to set the line relief valve for the boom cylinder head end. Loosen locknut (18) and turn adjustment screw (19) clockwise for one full turn. Tighten locknut (18) to a torque of 30 ± 2 N·m (20 ± 1 lb ft).

- Connect a 1000 kPa (145 psi) pressure gauge to pressure tap (17). This is used to monitor the relief pressure at the “PR” port of the boom lowering control valve.

- To adjust the line relief valve pressure setting of the boom cylinder head end, move the joystick for the boom until the boom is at the full BOOM RAISE position (full extension of boom cylinders). Hold the joystick for the boom in this position.

- Check the pressure in the boom cylinder head end on the pressure gauge at pressure tap (17) .

- Return the joystick for the boom to the NEUTRAL position.

- The pressure gauge reading should be 730 kPa (105 psi). If the pressure gauge reading at pressure tap (17) is not within the specification, adjust the line relief valve.

- Loosen locknut (18) on boom line relief valve (16). Turn adjustment screw (19) until the pressure gauge reading at pressure tap (17) is 730 kPa (105 psi).

Note: Always make final pressure adjustment on pressure rise.

Tighten locknut (18) to a torque of 30 ± 2 N·m (20 ± 1 lb ft).

- Adjust line relief valve (13) on the main control valve to the original setting. Loosen locknut (18) and turn adjustment screw (19) counterclockwise for one full turn. Tighten locknut (18) to a torque of 30 ± 2 N·m (20 ± 1 lb ft).

- To check line relief valve (13), move the joystick for the boom until the boom is at the full BOOM RAISE position (full extension of boom cylinders). Hold the joystick for the boom in this position.

- Check the pressure on the pressure gauge at pressure tap (2) .

- Return the joystick for the boom to the NEUTRAL position.

- Adjust line relief valve (13) on the main control valve to 31000 ± 1500 kPa (4500 ± 215 psi). Tighten locknut (18) to a torque of 30 ± 2 N·m (20 ± 1 lb ft).

Boom Cylinder Rod End

- To adjust the line relief valve pressure setting of the boom cylinder rod end, move the joystick for the boom until the boom is at the full BOOM LOWER position (full retraction of boom cylinders). Hold the joystick for the boom in this position.

Note: Use engine low idle speed in order to adjust the line relief valve pressure setting of the boom cylinder rod end. Refer to Testing and Adjusting, “Engine Performance – Test” for engine rpm settings.

- Check the pressure in the boom cylinder rod end on the pressure gauge at pressure tap (2) .

- Return the joystick for the boom to the NEUTRAL position.

- The pressure gauge reading should be 31000 ± 1500 kPa (4500 ± 215 psi). If the pressure gauge reading at pressure tap (2) is not within the specification, adjust the line relief valve.

- Loosen locknut (18) on boom line relief valve (10). Turn adjustment screw (19) until the pressure gauge reading at pressure tap (2) is 31000 ± 1500 kPa (4500 ± 215 psi).

Note: Always make final pressure adjustment on pressure rise.

- After completion of line relief valve adjustment, tighten locknut (18) to a torque of 30 ± 2 N·m (20 ± 1 lb ft).

Adjustment (Stick Cylinder)

Stick Cylinder Rod End

- Line relief valve (12) on the main control valve must be set at a higher pressure in order to set the line relief valve for the stick cylinder rod end. Loosen locknut (18) and turn adjustment screw (19) clockwise for one full turn. Tighten locknut (18) to a torque of 30 ± 2 N·m (20 ± 1 lb ft).

- Connect a 1000 kPa (145 psi) pressure gauge to pressure tap (15). This is used to monitor the relief pressure at the “PR” port of the stick lowering control valve.

- To adjust the line relief valve pressure setting of the stick cylinder rod end, move the joystick for the stick until the stick is at the full STICK OUT position (full retraction of stick cylinder). Hold the joystick for the stick in this position.

- Check the pressure in the stick cylinder rod end on the pressure gauge at pressure tap (15) .

- Return the joystick for the stick to the NEUTRAL position.

- The pressure gauge reading should be 730 kPa (105 psi). If the pressure gauge reading at pressure tap (15) is not within the specification, adjust the line relief valve.

- Loosen locknut (18) on stick line relief valve (14). Turn adjustment screw (19) until the pressure gauge reading at pressure tap (15) is 730 kPa (105 psi).

Note: Always make final pressure adjustment on pressure rise.

- After completion of line relief valve adjustment, tighten locknut (18) to a torque of 30 ± 2 N·m (20 ± 1 lb ft).

- Adjust line relief valve (12) on the main control valve to the original setting. Loosen locknut (18) and turn adjustment screw (19) counterclockwise for one full turn. Tighten locknut (18) to a torque of 30 ± 2 N·m (20 ± 1 lb ft).

- To check line relief valve (12), move the joystick for the stick until the stick is at the full STICK OUT position (full retraction of the stick cylinder). Hold the joystick for the stick in this position.

- Check the pressure on the pressure gauge at pressure tap (1) .

- Return the joystick for the stick to the NEUTRAL position.

- Adjust line relief valve (12) on the main control valve to 31000 ± 1500 kPa (4500 ± 215 psi). Tighten locknut (18) to a torque of 30 ± 2 N·m (20 ± 1 lb ft).

Stick Cylinder Head End

- To adjust the line relief valve pressure setting of the stick cylinder head end, move the joystick for the stick until the stick is at the full STICK IN position (full extension of stick cylinder). Hold the joystick for the stick in this position.

- Check the pressure in the stick cylinder head end on the pressure gauge at pressure tap (1) .

- Return the joystick for the stick to the NEUTRAL position.

- The pressure gauge reading should be 31000 ± 1500 kPa (4500 ± 215 psi). If the pressure gauge reading at pressure tap (1) is not within the specification, adjust the line relief valve.

- Loosen locknut (18) on stick line relief valve (9). Turn adjustment screw (19) until the pressure gauge reading at pressure tap (1) is 31000 ± 1500 kPa (4500 ± 215 psi).

Note: Always make final pressure adjustment on pressure rise.

- After completion of line relief valve adjustment, tighten locknut (18) to a torque of 30 ± 2 N·m (20 ± 1 lb ft).

Adjustment (Bucket Cylinder)

- To adjust the line relief valve pressure setting of the bucket cylinder head end, move the joystick for the bucket until the bucket is at the full BUCKET CLOSE position (full extension of bucket cylinder). Hold the joystick for the bucket in this position.

- Check the pressure in the bucket cylinder head end on the pressure gauge at pressure tap (2) .

- Return the joystick for the bucket to the NEUTRAL position.

- The pressure gauge reading should be 31000 ± 1500 kPa (4500 ± 215 psi). If the pressure gauge reading at pressure tap (2) is not within the specification, adjust the line relief valve.

- Loosen locknut (18) on bucket line relief valve (11). Turn adjustment screw (19) until the pressure gauge reading at pressure tap (2) is 31000 ± 1500 kPa (4500 ± 215 psi).

Note: Always make final pressure adjustment on pressure rise.

- After completion of line relief valve adjustment, tighten locknut (18) to a torque of 30 ± 2 N·m (20 ± 1 lb ft).