Removal Procedure

| Required Tools | |||

| Tool | Part Number | Part Description | Qty |

| A | 138-7573 | Link Bracket | 2 |

| B | 6V-8197 | Forcing Screw (M12 by 1.75 by 40 mm) | 2 |

Start By:

- Remove the swing motor. Refer to Disassembly and Assembly, “Swing Motor – Remove”.

|

|

| NOTICE |

|---|

|

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids. Refer to Special Publication, NENG2500, “Caterpillar Tools and Shop Products Guide” for tools and supplies suitable to collect and contain fluids on Caterpillar products. Dispose of all fluids according to local regulations and mandates. |

|

|

|

|

| NOTICE |

|---|

|

Keep all parts clean from contaminants. Contamination of the hydraulic system with foreign material will reduce the service life of the hydraulic system components. To prevent contaminants from entering the hydraulic system, always plug or cap the lines, fittings, or hoses as they are disconnected. Cover any disassembled components and clean them properly before assembly. Clean the hydraulic system properly after any major component exchange or especially after a component failure, to remove any contamination. |

|

|

- Drain the oil from the swing drive. The capacity of the swing drive is approximately 1.5 L (0.4 US gal). Refer to Operation and Maintenance Manual, SEBU7613, “Swing Drive Oil – Change” for the correct procedure for draining the swing drive.

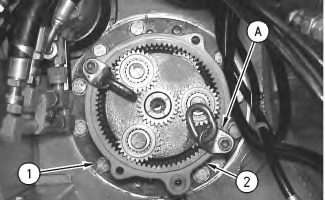

- Remove bolts (1) that hold the swing drive to the undercarriage frame. Use bolts (1) to attach Tooling (A) to swing drive (2) .

|

|

|

|

|

|

| Illustration 1 | g00907900 |

- Use a suitable lifting device to remove the swing drive. The weight of the swing drive is approximately 57 kg (125 lb).

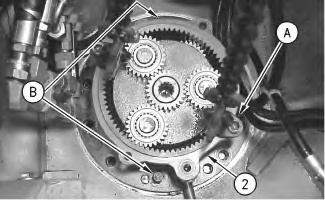

- Install Tooling (B) in each threaded hole in the swing drive housing. Tighten the forcing screws evenly in order to separate swing drive (2) from the dowels and the undercarriage frame.

|

|

|

|

|

|

| Illustration 2 | g00907920 |

- Remove swing drive (2) from the machine.

- Place the swing drive on wood blocks in order to prevent damage to the drive gear.