Note: The engine speed and/or the machine configuration that is used during this test can affect the results of this test. Refer to Testing and Adjusting, “Engine Performance – Test” for the engine speed that was used for this test. Refer to Testing and Adjusting, “Operational Checks” for the machine configurations that were used for this test.

Note: The relief valve pressure settings must be set to the relief valve pressure specification before performing this operational check. Refer to Testing and Adjusting, “Specifications”.

| Required Tools | ||

|---|---|---|

| Part Number | Description | Qty |

| 5P-3277 | Measuring Tape | 1 |

| Stopwatch | 1 | |

|

|

|

|

|

|

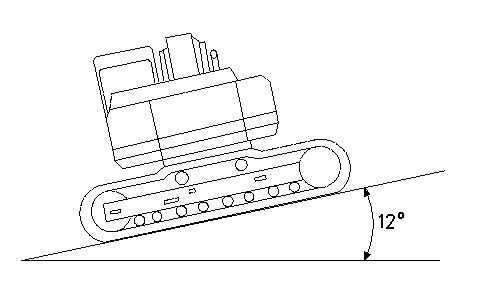

| Illustration 1 | g00298078 |

- Complete the following steps in order to measure the swing speed on a slope.

- Start the engine.

- Place the machine controls at the following settings: Engine speed dial “10” and Low idle switch OFF.

- Place the hydraulic activation control lever in the UNLOCKED position.

- Increase the hydraulic oil temperature to 55° ± 5°C (131° ± 9°F).

- The bucket should be empty.

- Position the machine on a slope of 12 degrees. Refer to Illustration 1.

- Position the implements at maximum reach and close the bucket. Position the bucket above the ground so that the bucket will not come in contact with any obstacles.

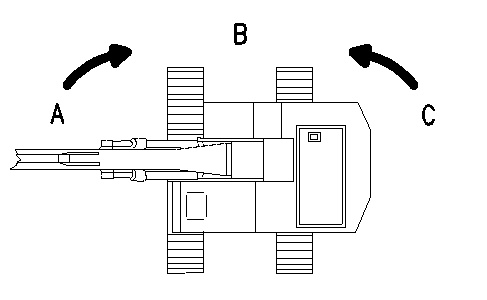

- Position the upper structure at position (A). The upper structure should be at a 90 degree angle to the lower structure. Refer to Illustration 2.

Illustration 2 g00298079 - Measure the time that is required to swing the upper structure from position (A) to position (B) .

- Position the upper structure at position (C). The upper structure should be at a 90 degree angle to the lower structure.

- Measure the time that is required to swing the upper structure from position (C) to position (B).

Table 2 Swing Time (seconds) Item New Rebuild Service Limit Right Swing 3.4 or less 3.9 or less 4.4 or less Left Swing

- Complete the following steps in order to measure the swing drift on a slope.

- Position the upper structure at position (A). The upper structure should be at a 90 degree angle to the lower structure. Refer to Illustration 3.

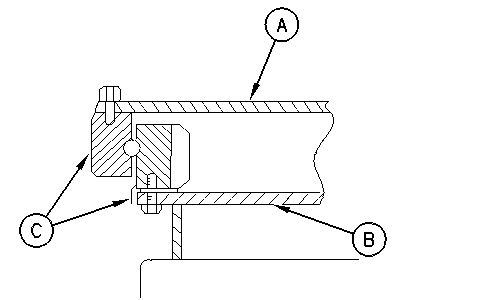

Illustration 3 g00298079 - To indicate the relationship of the two positions, put a mark (C) on the inner race and the outer race of the swing bearing. Refer to Illustration 4.

Illustration 4 g00293972 (A) Upper frame

(B) Undercarriage frame

(C) Marking

- Stop the engine.

- Leave the machine in this position for three minutes. Measure the swing drift on the circumference of the swing bearing.

- Start the engine.

- Position the upper structure at position (C). The upper structure should be at a 90 degree angle to the lower structure. Refer to Illustration 3.

- Repeat Steps 2.b through 2.d.

| Swing Drift mm (inch) | |||

|---|---|---|---|

| Item | New | Rebuild | Service Limit |

| Right Swing | 0 | 0 | 0 |

| Left Swing | |||