This section provides information about the reports and messages that are sent from the Product Link system. For information in order to access and change parameters, refer to Systems Operation, Troubleshooting, Testing and Adjusting, “Configuration”.

| PLM Report Configuration Parameters | |||

|---|---|---|---|

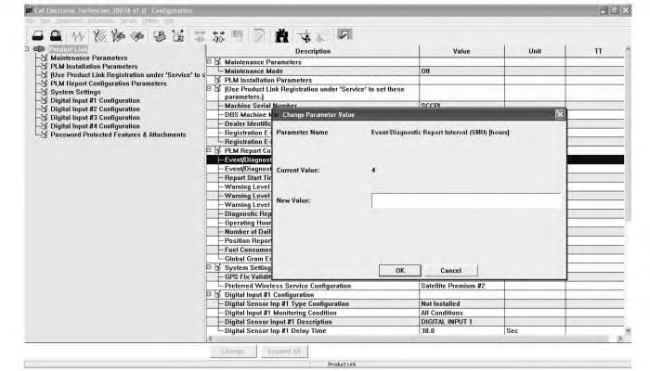

| Event/Diagnostic Report Interval (SMU) | The Event/Diagnostic Report Interval determines the time frame (measured in units of machine operating hours) the Product Link will report a repeat occurrence of an event/diagnostic code. | Enter the appropriate value for the reporting interval. | The minimum value is 4 hours. The default is 4 hours, meaning that an event/diagnostic update message will not be resent for a specific event/diagnostic until the machine has operated for 4 hours after the last transmitted occurrence of the event/diagnostic. At the next event/diagnostic occurrence after the time period elapses, another message will be sent. All events/diagnostics are recorded and may be viewed with Cat ET. A machine ECM will self erase a diagnostic if the diagnostic does not reappear after 100 operating hours. When this happens, the event history screen in the EM application will show a diagnostic that occurred 100 hours in the past, but that no longer shows up in Cat ET because the diagnostic has not reoccurred. |

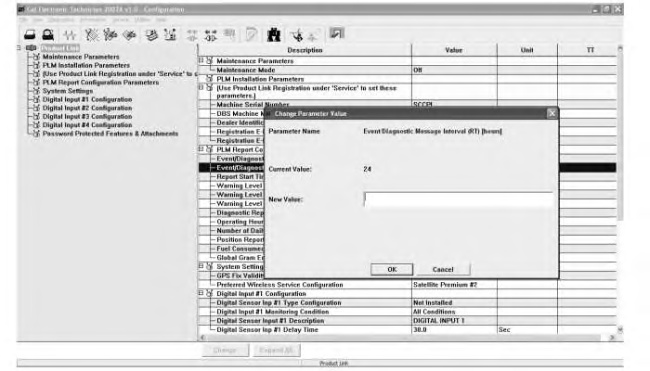

| Event/Diagnostic Message Interval (RT) | The Event/Diagnostic Message Interval (RT) parameter sets the time period (measured in units of real time (or calendar) hours) before an event/diagnostic message update is sent. This time period is calculated from the “Report Start Time”. An event/diagnostic scheduled message will be sent if any Event/Diagnostic code has occurred since the last scheduled message was sent. |

Enter the appropriate value for the reporting interval. | This value is only valid if the event or diagnostic report intervals are set to Next Scheduled. The minimum value is 20 hours. The default is 168 hours (1 week). |

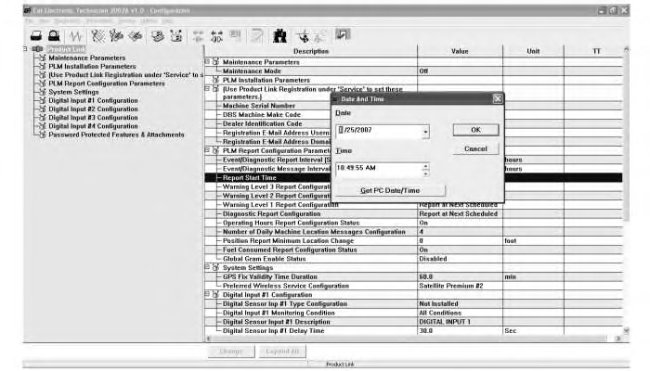

| Report Start Time | The Report Start Time parameter sets the time used as the initial report time for calculating when subsequent reports are sent. The Report Start Time parameter is also used as the basis for calculating “Next Scheduled ” events and diagnostic messages. Additional Information: Standard reports for Product Link are sent at time-based intervals. The messages will arrive as close as possible to the scheduled time. The messages may not arrive exactly on the scheduled time as the transmissions are automatically optimized for maximum efficiency of the Product Link system. |

Enter the correct local time value for the reporting start time. Consideration should be given to the time selected for the start time. For an example, if a machine normally operates between 7AM and 4PM, you would want to set the start time to a value somewhere between 7AM and 4PM, preferably, shortly after 7AM. |

A “Get PC Date/Time” button is supplied for easy entry of the current date and time. |

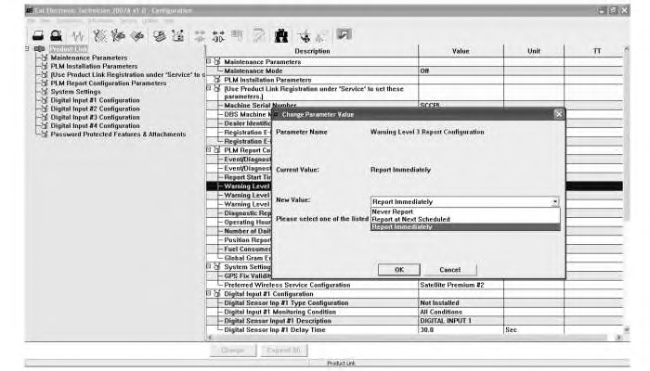

| Warning Level 1/2/3 Report Configuration | The Warning Level 1/2/3 Report Configuration parameter defines when to send messages from the Product Link system when a level 1, level 2, or level 3 event is reported from other ECMs (Electronic Control Modules) on the machine. The events reported match the events reported on Cat ET Logged Events screen. | To send a message immediately when an event occurs, select the “Immediate” value. | When an event reoccurs, a message is sent if the event/diagnostic report interval has expired. If the reporting interval has not expired, the event is only logged as an occurrence in the Product Link module. To queue messages about events and send events in a batch based on the next scheduled interval calculated from the report start time, select the “Next scheduled” value. To never log or send messages about events to the office, select the “Never” value. |

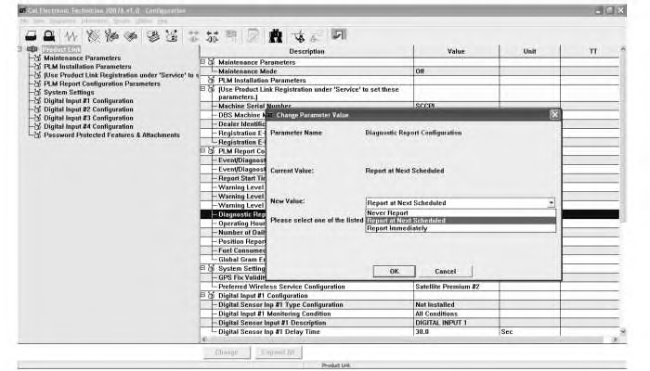

| Diagnostic Report Configuration | The Diagnostic Report Configuration parameter defines when to send messages from the Product Link system when a diagnostic event is reported from other Electronic Control Modules (ECMs) on the machine. The diagnostics reported match the diagnostics reported on the Cat ET Logged Diagnostics screens. | To send a message immediately when a diagnostic event occurs, select the “Immediate” value. Only logged events and diagnostics are sent in the message. |

When a diagnostic event reoccurs, a message is sent if the event/diagnostic report interval has expired. If the reporting interval has not expired, the diagnostic event is only logged as an occurrence in the Product Link module. To queue messages about diagnostic events and send events in a batch based on the next scheduled interval calculated from the report start time, select the “Next scheduled” value. To never log or send messages about diagnostic events to the office, select the “Never” value. |

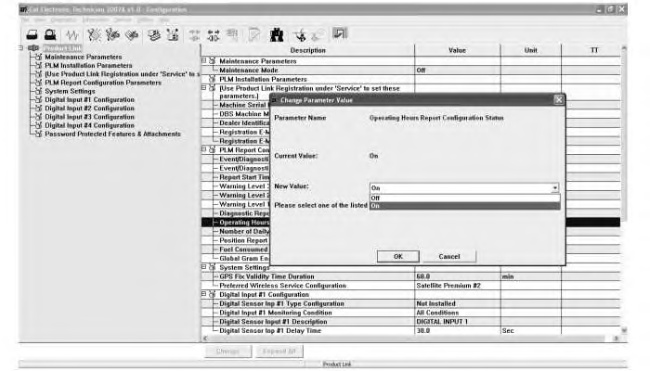

| Operating Hours Report Configuration Status | The “Operating Hours Report Configuration Status” parameter defines whether the operating hours will be displayed in Equipment Manager. | To have operating hours in Equipment Manager, select the “ON” value. To not have the operating hours displayed in Equipment Manager, select the “OFF” value. | |

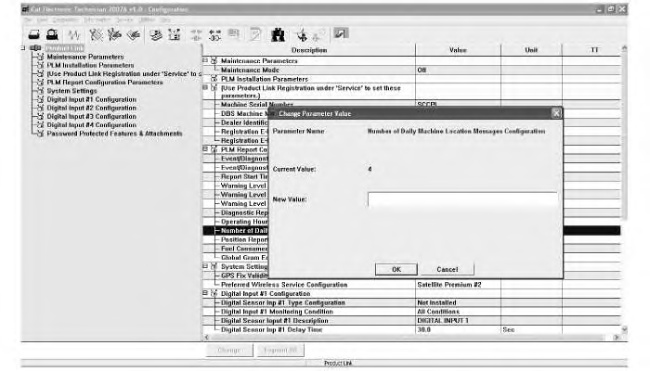

| Number of Daily Machine Location Messages Configuration | The Number of Daily Machine Location Messages Configuration parameter defines the number of machine location reports sent to the office. The reports are spread evenly across a 24 hour period with the first report sent at the defined Report Start Time. Currently you can choose to have zero to four position reports sent per day. If the machine has moved less than the position Report Minimum Location Change, Product Link will not send the position report. | Enter the number (0-4) of machine location reports to send daily to the office. | If you select four reports, the reports will be sent every 6 hours. If you select three reports, the reports are sent every 8 hours. |

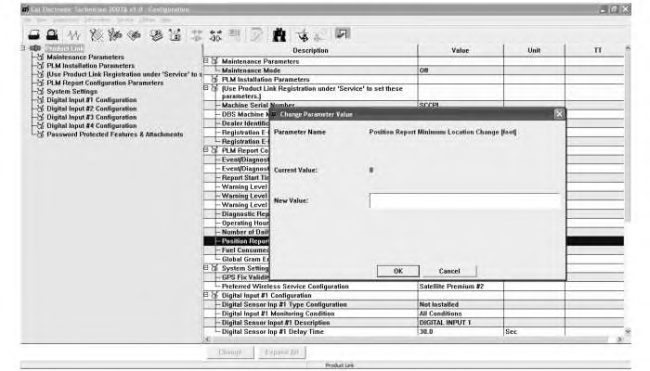

| Position Report Minimum Location Change | The Position Report Minimum Location Change sets the distance the machine must move in order for a position report to be queued. | If the value is set to ‘0’, the machine will send four position reports a day – regardless of movement. If the value is set to anything other than ‘0’, the machine will only send a position report if the minimum location requirement has been met – regardless of the value selected for the Number of Daily Machine Location Message Configuration. | In an existing PL121 system, the parameter automatically defaults to 0. In an existing PL321 system, the parameter will need to be changed to 0 – or the minimum distance preferred. |

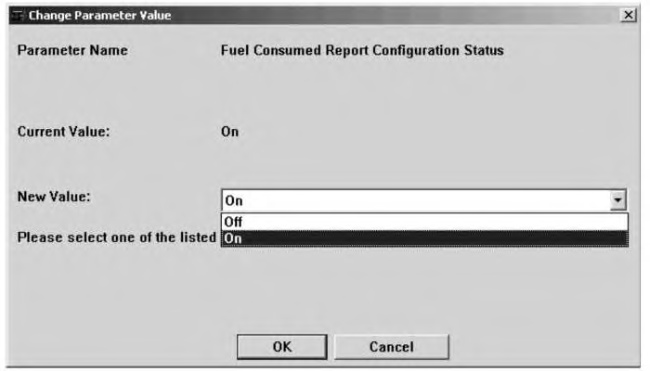

| Fuel Consumed Report Configuration Status | The Fuel Consumed Report Configuration Status parameter defines whether a fuel consumption report is sent as part of the standard message once per day. | To send a fuel consumption report as part of the once-per-day standard message, select the “On” value. In order to not send a fuel consumption report as part of the standard message once per day, select the “Off” value. |

Engine ECM must support this feature for Product Link to report the values. In the case of dual engine machines, Product Link will report the combined fuel usage from both engines as a single value to the BackOffice. If communication is lost with one of the engines, the last valid combined value will be reported. The value will be instead of the individual value. The combined value will be resumed once both engines respond on the CDL. |

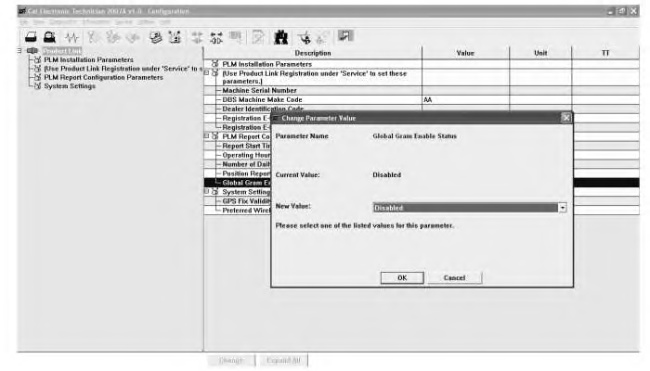

| Global Gram Enable Status | The Global Gram Enable Status configures how the Product Link sends messages when a ground station is not in view to the satellites. Global grams are used in areas of the world where there are no ground stations for VHF signal reception. | If the machine will operate in areas where there are no ground stations for VHF signal reception, select “Enabled”. If the machine will operate in areas where there are ground stations for VHF signal reception, leave the parameter set to the default “Disabled” | If there are any questions, consult your Caterpillar Dealer in order to determine if Global Grams are required. |

Refer to Table 1 for information about each of the following parameters.

“Event/Diagnostic Report Interval (SMU)” Parameter

|

|

|

|

|

|

| Illustration 1 | g01361846 |

|

Screen of “Event/Diagnostic Report Interval (SMU)” Parameter |

|

“Event/Diagnostic Message Interval (RT)” Parameter

|

|

|

|

|

|

| Illustration 2 | g01361848 |

|

Screen of “Event/Diagnostic Message Interval (RT)” Parameter |

|

“Report Start Time” Parameter

|

|

|

|

|

|

| Illustration 3 | g01361850 |

|

Screen of “Report Start Time” Parameter |

|

“Warning Level (1/2/3) Report Configuration” Parameter

|

|

|

|

|

|

| Illustration 4 | g01361851 |

|

Screen of “Warning Level (1/2/3) Report Configuration” Parameter |

|

The “Warning Level Report Configuration” parameter information is the same for each warning level report.

“Diagnostic Report Configuration” Parameter

|

|

|

|

|

|

| Illustration 5 | g01361853 |

|

Screen of “Diagnostic Report Configuration” Parameter |

|

“Operating Hours Report Configuration Status” Parameter

|

|

|

|

|

|

| Illustration 6 | g01361742 |

|

Screen of “Operating Hours Report Configuration Status” Parameter |

|

“Number of Daily Machine Location Message Configuration” Parameter

|

|

|

|

|

|

| Illustration 7 | g01361743 |

|

Screen of “Number of Daily Machine Location Message Configuration” Parameter |

|

“Position Report Minimum Location Change” Parameter

|

|

|

|

|

|

| Illustration 8 | g01361744 |

|

Screen of “Position report Minimum Location Change” Parameter |

|

“Fuel Consumed Report Configuration Status” Parameter

|

|

|

|

|

|

| Illustration 9 | g01361745 |

|

Screen of “Fuel Consumed Report Configuration Status” Parameter |

|

“Global Gram Enable Status” Parameter

|

|

|

|

|

|

| Illustration 10 | g01361286 |

|

Screen of “Global Gram Enable Status” Parameter |

|