Installation Of PL121SR Only

Refer to the Systems Operation, Troubleshooting, Testing and Adjusting, “Configuration” for the following information:

- Preparing a laptop computer to interface with the Product Link system

- Accessing the parameters for installation

- Changing the parameters for installation

|

|

|

|

|

|

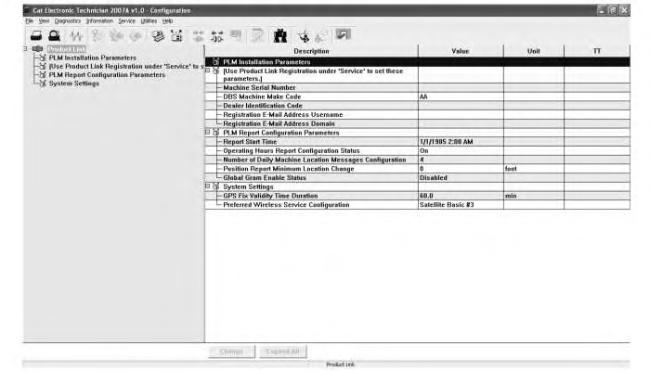

| Illustration 1 | g01360584 |

|

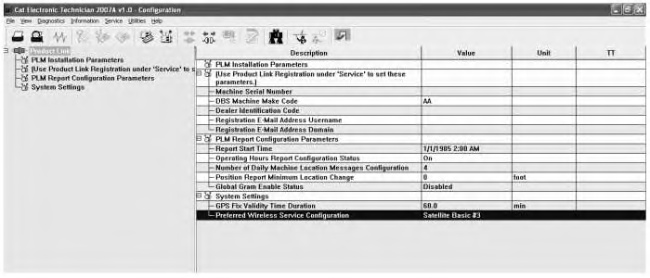

Configuration Screen of CAT ET for PL121 |

|

| Parameter Table | |||

|---|---|---|---|

| Parameter | Description | Configuration | Notes |

| Machine Serial Number | The Machine Serial Number is used by the Product Link system for routing and displaying information by the machine. | For a non-Caterpillar machine, enter the machine serial number. For Caterpillar machines, enter the last eight characters of the new 17 character PIN for this value. Refer to Illustration 2. | The maximum length is 17 characters. Do not start the serial number with a space. Do not abbreviate the serial number. For example, “1AA00123” should not be shortened to “1AA123”. Do not use uppercase “O” instead of zero “0”. |

| DBS Machine Make Code | The DBS Machine Make Code parameter defines the make of the machine where Product Link is installed. | Enter the appropriate value for the DBS Machine Make Code. | Only two upper case alpha-numeric characters are allowed for this value. “AA” is the default code that represents only a Caterpillar machine. All other codes of manufacturer’s are determined by individual dealers. Refer to your work order or your DBS dealers administrator for the correct code to use on non-Caterpillar machines. |

| Dealer Identification Code | The Dealer Identification Code is utilized by the Product Link system for routing and displaying information so that the information is visible to personnel in a dealership office. | Enter the correct value for the Dealer Identification Code. | This value can contain up to six characters that are uppercase and alphanumeric characters. All machines must be registered with the ID number for the main branch of the dealership. |

| Registration E-Mail Address Username | The Registration E-Mail Address Username in conjunction with the Registration E-Mail Address Domain defines the e-mail address that should receive confirmation of the machines registration status. | In the registration screen, the username and domain are entered as a complete email address. (yourname@youremail.com) | The Registration E-Mail Address Username refers to portion of the e-mail address before the @ symbol. ( If your email address was yourname@youremail.com, the username would be “yourname”) |

| Registration E-Mail Address Domain | The Registration E-Mail Address Domain in conjunction with the Registration E-Mail Address Username defines the e-mail address that should receive confirmation of the machines registration status | In the registration screen, the username and domain are entered as a complete email address. (yourname@youremail.com) | The Registration E-Mail Address Domain refers to portion of the e-mail address after the @ symbol. (If your email address was yourname@youremail.com, the domain would be “youremail.com”) |

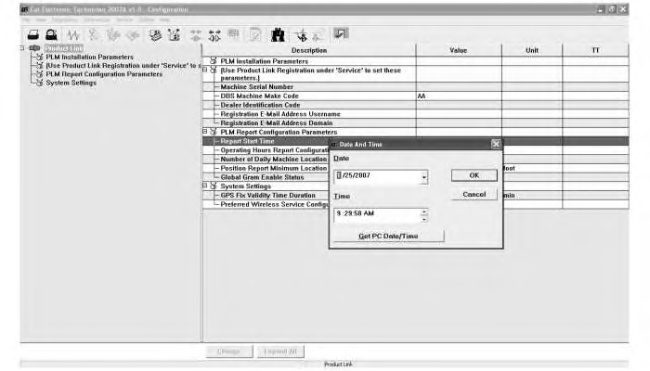

| Report Start Time | The Report Start Time parameter sets the time used as the initial report time for calculating when subsequent reports are sent. The Report Start Time parameter is also used as the basis for calculating “Next Scheduled” events and diagnostic messages. Additional Information Standard reports for Product Link are sent at time-based intervals. Position reports are sent every 6 hours. A service meter report is sent every 24 hours. The messages will arrive as close as possible to the scheduled time. The messages may not arrive exactly on the scheduled time as the transmissions are automatically optimized for maximum efficiency of the Product Link system. |

Enter the correct local time value for the reporting start time. Consideration should be given to the time selected for the start time. For an example, if a machine normally operates between 7AM and 4PM, you would want to set the start time to a value somewhere between 7AM and 4PM, preferably, shortly after 7AM. |

A “Get PC Date/Time” button is supplied for an easy entry of the current date and time. |

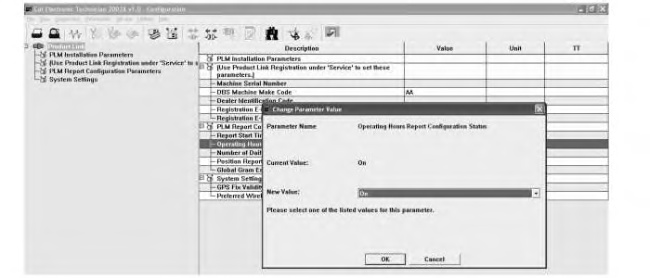

| Operating Hours Report Configuration Status | The Operating Hours Report Configuration Status parameter defines whether once-per-day standard message is sent. | To send the standard message once per day, select the “On” value. In order to not send a standard message once per day, select the”Off” value. | |

| Number of Daily Machine Location Messages Configuration | The Number of Daily Machine Location Messages Configuration parameter defines the number of machine location reports sent to the office. The reports are spread evenly across a 24 hour period with the first report sent at the defined Report Start Time. Currently you can choose to have (0 – 4) position reports sent per day. |

Enter the number (0 – 4) of machine location reports to send daily to the office. | If you select four reports, the reports will be sent every 6 hours. If you select three reports, the reports are sent every 8 hours and so on. |

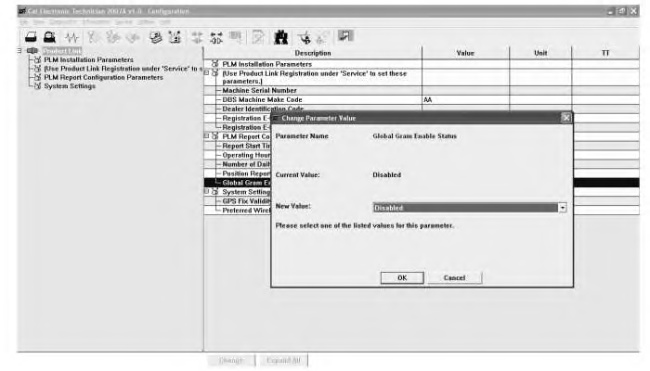

| Global Gram Enable Status | The Global Gram Enable Status configures how the Product Link sends messages when a ground station is not in view to the satellites. Global grams are used in areas of the world where there are no ground stations for Orbcomm signal reception. | If the machine will operate in areas where there are no ground stations for Orbcomm signal reception, select “Enabled”. If the machine will operate in areas where there are ground stations for Orbcomm signal reception, leave the parameter set to the default “Disabled”. |

If there are any questions, consult your Cat dealer in order to determine if Global Grams are required. |

| Position Report Minimum Location Change | The Position Report Minimum Location Change sets the distance the machine must move in order for a position report to be queued. | If the value is set to ‘0’, the machine will send four position reports a day – regardless of movement. If the value is set to anything other than ‘0’, the machine will only send a position report if the minimum location requirement has been met – regardless of the value selected for the Number of Daily Machine Location Message Configuration. | In an existing PL121 system or a new PL321 system, the parameter automatically defaults to 0. In an existing PL321 system, the parameter will need to be changed to 0 – or the minimum distance preferred. |

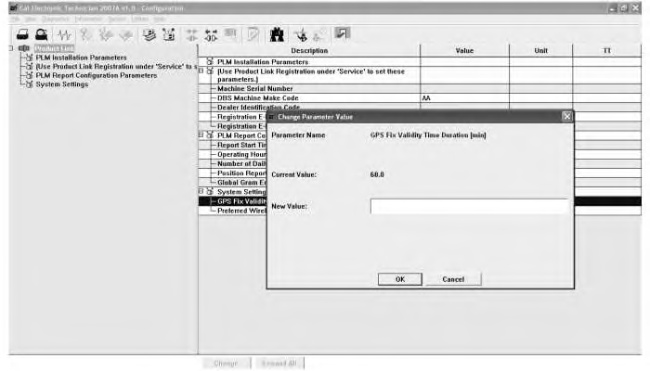

| GPS Fix Validity Time Duration | The GPS Fix Validity Time Duration parameter allows users to select the amount of time a GPS fix is required before a position is considered ‘Valid’ or ‘Invalid’. | The minimum amount of time is 30 minutes. The maximum is 1440 minutes. The default is 60 minutes. | |

| Preferred Wireless Service Configuration | The Preferred Wireless Service Configuration parameter allows users to select the correct wireless service for wireless devices. | Satellite Basic “#3” is the default for the Preferred Wireless Service Configuration value for the PL121SR. | This parameter is not configurable. |

Machine Serial Number

Note: The serial number for a non-Caterpillar machine can be any alphanumeric characters up to 17 characters long such as “147433789DBS”. When using a non-Caterpillar machine serial number, be sure to change the Make Code from “AA” to the appropriate 2-character value.

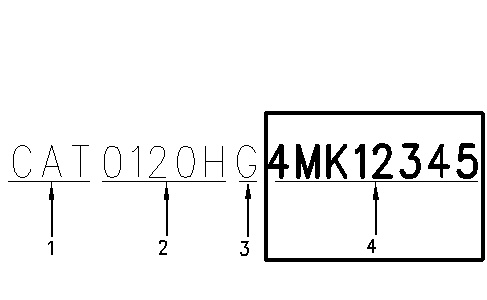

For Caterpillar machines, enter only the last eight digits of the “Machine Serial Number”. Refer to Illustration 2 and Illustration 3 for examples of two machine serial numbers.

Note: “PLM Installation Parameters” section cannot be changed in the Configuration screen. These parameters must be changed using the “Service ” menu, “Product Link Registration” drop-down menu option.

First Quarter 2001, the Caterpillar Product Identification Number (PIN) changed from 8 characters to 17 characters. The “Product ID” that is required by the Product Link System is the last eight digits. Refer to Item (4) in Illustration 2.

|

|

|

|

|

|

| Illustration 2 | g01126595 |

|

(1) Caterpillar’s World Manufacturing Code (characters 1 – 3) (2) Machine description (characters 4 – 8) (3) Check character (character 9) (4) Machine Indicator Section (MIS) or Product Sequence Number (characters 10 – 17). These characters were previously referred to as the Serial Number. |

|

“Product Link Registration” Screen

|

|

|

|

|

|

| Illustration 3 | g01360675 |

|

Screen of New Configuration Method via “Service” Menu, “Product Link Registration” Drop-down Menu |

|

“Report Start Time” Screen

|

|

|

|

|

|

| Illustration 4 | g01361252 |

|

“Report Start Time” Screen |

|

“Operating Hours Report Configuration” Screen

|

|

|

|

|

|

| Illustration 5 | g01361257 |

|

“Operating Hours Report Configuration” Screen |

|

“Number of Daily Machine Location Messages” Screen

|

|

|

|

|

|

| Illustration 6 | g01361269 |

|

“Number of Daily Machine Location Messages” Screen |

|

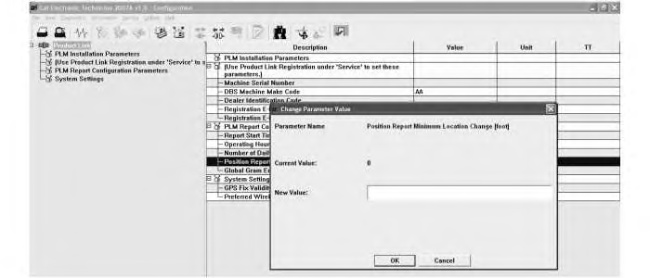

“Position Report Minimum Location Change” Screen

|

|

|

|

|

|

| Illustration 7 | g01360603 |

|

“Position Report Minimum Location Change” Screen |

|

“Global Gram Enable Status” Screen

|

|

|

|

|

|

| Illustration 8 | g01361286 |

|

“Global Gram Enable Status” Screen |

|

“GPS Fix Validity Time Duration” Screen

|

|

|

|

|

|

| Illustration 9 | g01360606 |

|

“GPS Fix Validity Time Duration” Screen |

|

“Preferred Wireless Service Configuration” Screen

|

|

|

|

|

|

| Illustration 10 | g01361300 |

|

“Preferred Wireless Service Configuration” Screen |

|