Connecting a Computer to the Product Link System

Required Software

Verify that Product Link has installed the latest flash file.

Supported Connections for Hardware

The PL121SR Radio and PL300 ECM are configured with CAT ET by using the following communications interfaces:

PL121SR Installations Only – The 245-7310 Control Harness Assembly (Serial Service Cable) is connected between the PC serial port and the serial service connector on the radio legacy harness or the conversion harness. The CAT ET “Communications Interface Device” is configured for “Embedded Communications Adapter”.

PL121SR plus the PL300 Installations Only – The 171-4400 Communication Adapter Group hardware is connected between the machine service connector and the PC serial port or parallel port. The CAT ET “Communications Interface Device” is configured for the “Caterpillar Communications Adapter II (RP1210)”.

Note: The configuration parameters for the “Communications Interface Device” are found in CAT ET under “Utilities” menu, “Preferences” drop-down menu.

Configure Computer Interface Communications for CAT ET

The following examples of screens show configuring communications for the computer in order to use CAT ET.

- Use the 245-7310 Serial Service cable to connect a computer with the required CAT ET software to the serial service connector of the wiring harness.

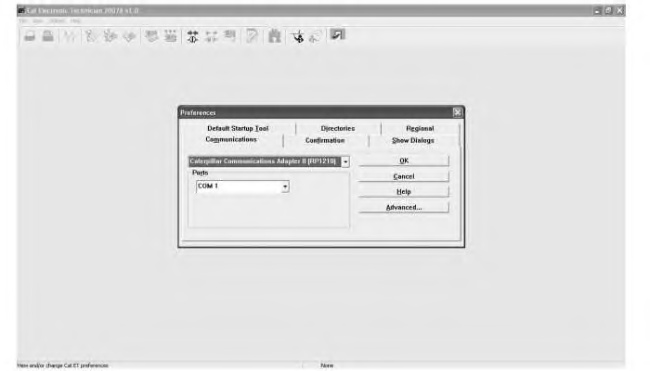

- Select “Utility” on the tool bar.

- From the drop-down menu, select “Preference”.

|

|

|

|

|

|

| Illustration 1 | g01361214 |

|

“Preference” Section for CAT ET |

|

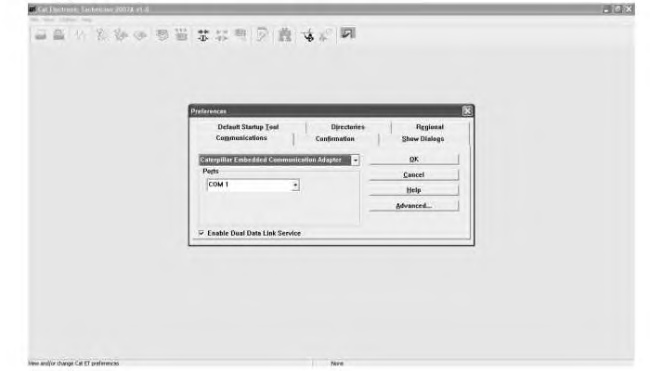

- From the “Communications” tab, click the drop-down menu and select “Caterpillar Embedded Communication Adaptor”.

|

|

|

|

|

|

| Illustration 2 | g01361220 |

|

“Preference” Section for CAT ET |

|

Configure Product Link PL121SR Radio and PL300 ECM

This section provides information for the user in order to configure the parameters required for the Product Link system during installation. After the “Machine Serial Number”,”Machine Make Code”, and the “Dealer ID” are set, the unit will auto-register the Product Link system.

There are a number of parameters that need configured for the Product Link. There are default values that are loaded. Many of the default values are acceptable in most applications. However, care must be followed in setting these parameters to ensure proper operation. Also, care will help avoid increased costs for messaging. Enter the “Product Link Module (PLM) Installation Parameters” last to ensure proper registration. Select the configuration screen by selecting the icon on the tool bar or by using the pull-down menus from the menu bar.

Two communications adapters are available in order to flash program the electronic control modules. The 7X-1700 Communications Adapter can be used, or the 171-4400 Communication Adapter II can be used.

After the Product Link has been configured, the radio must be registered with the Equipment Manager system. If installing only the PL121SR Radio (no PL300 ECM), configure the radio as described in PL121SR “Installation Parameters Configure – Radio Only” section. If installing the PL121SR and the PL300 ECM, configure the radio and ECM as described in the “Installation Parameters Configure for PL321SR System (PL121SR Radio and PL300 ECM)”.

- There are three ways to access the configuration screen. Select one of the following options:

- Select “Service” and select “Configure” on the menu bar.

- Press the “F5” key.

- Select “ECM Configuration Icon” on the tool bar.

- Ensure that steps have been taken in order to connect the computer with CAT ET software properly to the Product Link system. Refer to “Connecting a Computer to the Product Link System”.

- Click the “Connect” icon or click “File” on the menu bar. Click “Connect” from the pull-down menu in order to establish communication with the PL121SR radio.

- After the computer has connected to the PL121SR radio, click the “Configuration Tool” icon. Select the “Service” menu, “Configuration” drop-down menu in order to view the Configuration screen.

- Double click the desired parameter or select the desired parameter. Click “Change”. A dialog box will appear with a scroll down list that will show all of the possible parameter values.

- Click “OK” after changing each parameter in order to return to the Configuration screen.

Refer to the Systems Operation, Troubleshooting, Testing and Adjusting, “Commands” for information about registering the Product Link system.