The configuration mode will display information about the machine and changes in various values.

|

|

|

|

|

|

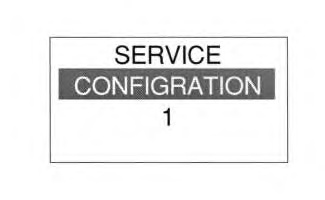

| Illustration 1 | g00770916 |

- Enter the service mode. Select the “CONFIGURATION” option from the menu by using the keys for direction.

- The third line in the above illustration indicates the configuration ID. The settings that correspond to the respective ID numbers are listed in the following table. Each respective ID is classified in either the “display only” or the setting for the ID. In order to change the ID, use the keys for direction and highlight the fourth line. After the ID has been changed, press the “setting” key. When the area that is highlighted moves to the third line, the change has been completed.

|

|

|

|

|

|

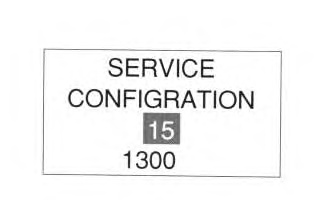

| Illustration 2 | g00687754 |

- In order to clear the setting, highlight the word “STANDBY” in the fourth line and press the “setting” key.

|

|

|

|

|

|

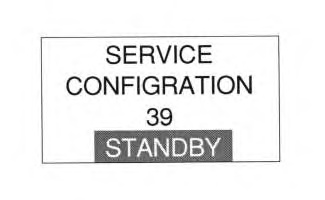

| Illustration 3 | g00687765 |

- The above illustration shows the screen that confirms the “clear” operation. When “CLEAR?” is being displayed, press the “OK” key. This operation has been completed.

|

|

|

|

|

|

| Illustration 4 | g00687786 |

Note: See the appropriate service manual for the tool control for the parameters that are not listed.

| Items For Configuration | ||

| ID | Display Content | Description / Change Method |

| 1 | Model information | Display only (Model name- Model type) |

| 2 | Type of hydraulic oil | Mineral oil: MINERAL Vegetable oil : BIO OIL |

| 3 | Travel alarm status | Equipped: INSTALLED Non-equipped: NOT INSTALLED |

| 4 | Water separator Contact type of level switch | NORMALLY OPEN NORMALLY CLOSE Non-equipped: NOT INSTALLED |

| 5 | Contact type of NO. 1 fuel filter switch | NORMALLY OPEN NORMALLY CLOSE Non-equipped: NOT INSTALLED |

| 6 | Contact type of clogged second fuel filter switch | NORMALLY OPEN NORMALLY CLOSE Non-equipped: NOT INSTALLED |

| 7 | Contact type of clogged special filter switch | NORMALLY OPEN NORMALLY CLOSE Non-equipped: NOT INSTALLED |

| 8 | Contact type of automatic greasing failure switch | NORMALLY OPEN NORMALLY CLOSE Non-equipped: NOT INSTALLED |

| 9 | Overload warning sensor status | Equipped: INSTALLED Non-equipped: NOT INSTALLED |

| 10 | Pressure of overload warning Units: kPa (PSI) |

Upper limit: 40000 kPa (5801 psi) Lower Limit: 0 Kpa (0 psi) 1 step: 100 kPa (14 psi) |

| 301 | Switching pressure to low speed of automatic travel speed change Units: kPa (PSI) |

Upper limit: 40000 kPa (5801 psi) Lower Limit: 0 Kpa (0 psi) 1 step: 100 kPa (14 psi) |

| 302 | Switching pressure to high speed of automatic travel speed change Units: kPa (PSI) |

Upper limit: 40000 kPa (5801 psi) Lower Limit: 0 Kpa (0 psi) 1 step: 100 kPa (14 psi) |

| 303 | Switching time to low speed of automatic travel speed change Units: Second |

Upper limit: 25.0 sec Lower limit: 0.0 sec 1 step: 0.1 sec |

| 304 | Switching time to high speed of automatic travel speed change | Upper limit: 25.0 sec Lower limit: 0.0 sec 1 step: 0.1 sec |

| 305 | Setting speed of one-touch low idle Units: rpm |

Upper limit: Initial speed at Dial position 10 Lower limit: Initial speed at Dial position 1 1 step: 10 rpm |

| 306 | AEC 2nd stage setting speed Units: rpm |

Upper limit: Initial rpm at Dial position 10 Lower limit: Initial rpm at Dial position 1 1 step: 10 rpm |

| 307 | AEC 2nd stage operation time Units: Second |

Upper limit: 25.0 sec Lower limit: 0.0 sec 1 step: 0.1 sec |

| 308 | Setting change of setting speed for current Dial position Units: rpm |

Upper limit: One step up dial setting less than -50 rpm Lower limit: One step down setting speed over +50 rpm Max. value: Initial rpm at Dial position 10 Min. value: Initial rpm at Dial position 1 1 step: 10 rpm |

| 309 | Setting change of torque distribution for the current Dial position Units: % |

0.1% unit display using the decimal point Upper limit value: 100.0% (200.0% for 321C) Lower limit value: 0.0% 1 step: 1.0% (0.1% for 321C) Reset operation is possible |

| 401 | Engine oil recommended change time Units: Hours |

Upper limit: 25500 hours Lower limit: 0 hours 1 step: 100 hours (50 hours for 321C) “0 hour” is used as non-equipped. |

| 402 | Engine oil filter recommended change time Units: Hours |

Upper limit: 25500 hours Lower limit: 0 hours 1 step: 100 hours (50 hours for 321C) “0 hour” is used as non-equipped. |

| 403 | Fuel filter recommended replacement time Units: Hours |

Upper limit: 25500 hour Lower limit: 0 hour 1 step: 100 hours (50 hours for 321C) “0 hour” is used as non-equipped. |

| 404 | Primary filter recommended replacement time Units: Hours |

Upper limit: 25500 hours Lower limit: 0 hours 1 step: 100 hours (50 hours for 321C) “0 hour” is used as non-equipped. |

| 405 | Swing drive oil recommended replacement time Units: Hours |

Upper limit: 25500 hours Lower limit: 0 hours 1 step: 100 hours (50 hours for 321C) “0 hour” is used as non-equipped. |

| 406 | Pilot oil filter recommended replacement time Units: Hours |

Upper limit: 25500 hours Lower limit: 0 hours 1 step: 100 hours (50 hours for 321C) “0 hour” is used as non-equipped. |

| 407 | Drain oil filter recommended replacement time Units: Hours |

Upper limit: 25500 hours Lower limit: 0 hours 1 step: 100 hours (50 hours for 321C) “0 hour” is used as non-equipped. |

| 408 | Hydraulic return filter recommended replacement time Units: Hours |

Upper limit: 25500 hours Lower limit: 0 hours 1 step: 100 hours (50 hours for 321C) “0 hour” is used as non-equipped. |

| 409 | Final drive oil change time Units: Hours |

Upper limit: 25500 hours Lower limit: 0 hours 1 step: 100 hours (50 hours for 321C) “0 hour” is used as non-equipped. |

| 410 | Hydraulic oil recommended change time Units: Hours |

Upper limit: 25500 hours Lower limit: 0 hours 1 step: 100 hours (50 hours for 321C) “0 hour” is used as non-equipped. |

| 411 | Coolant recommended change time Units: Hours |

Upper limit: 25500 hours Lower limit: 0 hours 1 step: 100 hours (50 hours for 321C) “0 hour” is used as non-equipped. |

| 501 | Adjustment of load input Power shift response |

Upper limit: 128 Lower limit: -127 1 step: 1 |

| 502 | Memory mode setting of automatic engine speed control when key is in the ON position. | At memory mode: ENABLE At AEC: OFF |

| 601 | Clear engine speed dial #’s back to default setting Refer to ID 308 |

Normal: Standby In clear demand: CLEAR? After performing clear: CLEARED |

| 602 | All clear of dial torque distribution setting change Refer to ID 309 |

Normal: STANDBY In clear demand: CLEAR? After performing clear: CLEARED |

| 603 | All clear of operating time NOTE: Please use care when using this feature. |

Normal: STANDBY In clear demand: CLEAR? After performing clear: CLEARED |

| 604 | All clear of elapsed time for filter/fluid NOTE: Please use care when using this feature. |

Normal: STANDBY In clear demand: CLEAR? After performing clear: CLEARED |

| 605 | All clear of logged error | Normal: STANDBY In clear demand: CLEAR? After performing clear: CLEARED |