|

|

|

|

|

|

| Illustration 1 | g00921609 |

|

(1) Machine electronic control module (2) Solenoid valve group (3) Solenoid valve for one pump/two pump flow (4) Solenoid valve for one pump/two pump flow (5) Solenoid valve for one-way/two-way flow (6) Right foot pedal (7) Left foot pedal (8) Pilot valves (9) Work tool pressure switch for auxiliary control valve (10) Work tool pressure switch for auxiliary control valve (medium pressure) (11) Relief valve (12) Solenoid valve for one-way flow (13) Solenoid valve for one-way flow (14) Line for work tool (15) Line for work tool (16) Main control valve (17) Attachment control valve (18) Proportional solenoid valve (19) Pilot pump (20) Drive pump (21) Idler pump (22) Hydraulic tank (23) Pilot manifold (24) Auxiliary control valve (25) Relief valve (26) Relief valve (27) Auxiliary control valve (medium pressure) (28) Relief valve (29) Relief valve (30) Line for medium pressure (31) Line for medium pressure |

|

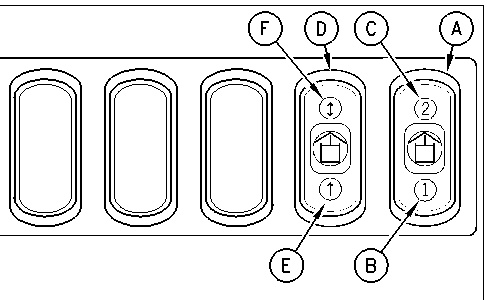

| Switch “A” for one pump/two pump flow | Switch “D” for one-way/two-way flow | |

| One pump One-way flow |

B | E |

| One pump Two-way flow |

B | F |

| Two pump One-way flow |

C | E |

| Two pump Two-way flow |

C | F |

The combined function hydraulic system that is present on excavators that are equipped with a System 11 combines the features of the one-way/two-way flow system with the features of the one pump/two pump flow system.

A medium pressure circuit is present on the excavators that are equipped with a System 11. The medium pressure circuit for the work tool operates in the same manner for all machines. The descriptions refer to the operation of a rotating grapple. The medium pressure circuit can operate any work tool that utilizes an auxiliary circuit.

The one pump flow system allows flow from one pump to power a work tool. All of the load is placed on a single pump. One pump flow is used for work tools that require low flow rates for actuation.

The two pump flow system allows the combined flow from both pumps to power a work tool. Rather than placing all of the load on a single pump, the two pump flow system allows the two pumps to provide flow equally. Two pump flow is used for work tools that require high flow rates for actuation. Two pump flow distributes the load equally for work tools that are used extensively.

A rocker switch is used in order to change between one-way/two-way flow and one pump/two pump flow. The rocker switch assembly is located in the cab of the machines that are equipped with a System 11.

|

|

|

|

|

|

| Illustration 2 | g00994458 |

|

(A) Rocker switch for one pump flow and two pump flow (B) Switch position for one pump flow (C) Switch position for two pump flow (D) Rocker switch for one-way flow and two-way flow (E) Switch position for one-way flow (F) Switch position for Two-way flow |

|

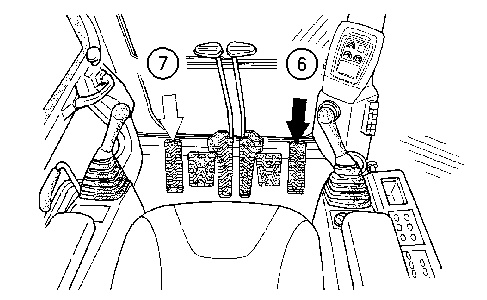

The work tool is operated by right foot pedal (6) . The medium pressure circuit is operated by left foot pedal (7) . Both pedals are located in the cab.

|

|

|

|

|

|

| Illustration 3 | g00847513 |

|

(6) Right foot pedal for the work tool (7) Left foot pedal for the medium pressure circuit |

|

One-Way Flow from One Pump “Tool #1”

The default parameter values for “TOOL#1” are for one-way hydraulic oil flow from one main pump. Refer to Testing and Adjusting, “System 11: Default Value of Work Tool Parameters” for the Tool Control System.

The flow to the work tool can be set by using the monitor or ET.

Operation

| Work Tool Circuits and Positions for the Rocker Switches One Pump Flow One-Way Flow |

|

| Rocker Switch (A) | B |

| Rocker Switch (D) | E |

Move rocker switch (A) to position (B) . This de-energizes the solenoid for one pump/two pump flow (3) and the solenoid for one pump/two pump flow (4) . Move rocker switch (D) to position (E) . This energizes the solenoid for one-way flow (12) and the solenoid for one-way flow (13) . This will also de-energize the solenoid for two-way flow (5) .

Pilot pump (19) supplies oil to pilot manifold (23) . When the hydraulic activation lever is moved to the UNLOCK position, pilot oil flows from pilot manifold (23) to right foot pedal (6) . When right foot pedal (6) is depressed FORWARD, pilot oil flows to auxiliary control valve (24) . The pilot oil will shift the spool in auxiliary control valve (24) to the DOWNWARD position. This allows oil from drive pump (20) to flow through the valve. The pump oil flows through the line for the work tool (14) to the work tool. The pump oil flows through the solenoid valve for one-way flow (13) to relief valve (11) . The working pressure for the work tool is controlled by relief valve (11) . Return oil flows through the line for the work tool (15) or through the solenoid valve for one-way flow (12) and back to hydraulic tank (22) .

During the operation of the work tool, work tool pressure switch (10) senses pilot pressure.

Pressure switch (10) signals the machine electronic control module. The machine ECM sends a signal to the proportional solenoid valve for negative flow control (18) . Negative flow control pressure in the center bypass passage is blocked when the auxiliary stems shift DOWNWARD. The machine ECM has programmed parameter values “101”, “102”, and “103” for flow and pressure for the work tool. The machine ECM calculates the minimum negative flow control pressure that will be supplied to the pump regulator. When the work tool is activated, proportional solenoid valve (18) receives a signal from the machine ECM. The signal is a result of the calculation. The negative flow control pressure forces the swashplate in the pump to the correct angle to limit the flow and pressure.

The pressure setting for the relief valve must be reset to the specification of the supplier for the work tool that is being used.

One-Way Flow From Two Pumps “Tool #3”

Description

The default parameter values for “TOOL#3” are for one-way hydraulic oil flow from two main pumps. Refer to Testing and Adjusting, “System 11: Default Value of Work Tool Parameters” for the Tool Control System.

The flow to the work tool can be set by using the monitor or ET.

Operation

| Work Tool Circuits and Positions for the Rocker Switches Two Pump Flow One-Way Flow |

|

| Rocker Switch (A) | C |

| Rocker Switch (D) | E |

Move rocker switch (A) to position (C) . This energizes the solenoid for one pump/two pump flow (3) and the solenoid for one pump/two pump flow (4) . Move rocker switch (D) to position (E) . This energizes the solenoid for one-way flow (12) and the solenoid for one-way flow (13) . This will also de-energize the solenoid for two-way flow (5) .

Pilot pump (19) supplies oil to pilot manifold (23) . When the hydraulic activation lever is moved to the UNLOCK position, pilot oil flows from pilot manifold (23) to right foot pedal (6) . When right foot pedal (6) is depressed FORWARD, pilot oil flows to auxiliary control valve (24) and to attachment control valve (17) . The pilot oil will shift the spool in each of the valves to the DOWNWARD position. This allows oil from drive pump (20) to flow through auxiliary control valve (24) . This also allows oil from idler pump (21) to flow through attachment control valve (17) . The hydraulic oil from the two pumps combines after the oil passes through both valves. The pump oil flows through the line for the work tool (14) to the work tool. The pump oil flows through the solenoid valve for one-way flow (13) to relief valve (11) . The working pressure for the work tool is controlled by relief valve (11) . Return oil flows through the line for the work tool (15) or through the solenoid valve for one-way flow (12) and back to hydraulic tank (22) .

During the operation of the work tool, the work tool pressure switch (10) senses pilot pressure.

Pressure switch (10) signals the machine electronic control module . The machine ECM sends a signal to the proportional solenoid valve for negative flow control (18) . Negative flow control pressure in the center bypass passage is blocked when the valve spools shift DOWNWARD. The machine ECM has programmed parameter values “101”, “102”, and “103” for flow and pressure for the work tool. The machine ECM calculates the minimum negative flow control pressure that will be supplied to the pump regulator. When the work tool is activated, proportional solenoid valve (18) receives a signal from the machine ECM. The signal is a result of the calculation. The negative flow control pressure forces the swashplate in drive pump (20) and idler pump (21) to the correct angle to limit the flow and pressure.

The pressure setting for the relief valve must be reset to the specification of the supplier for the work tool that is being used.

Two-Way Flow From One Pump “TOOL#2”

Description

The default parameter values for “TOOL#2” are for two-way hydraulic oil flow from one main pump. Refer to Testing and Adjusting, “System 11: Default Value of Work Tool Parameters” for the Tool Control System.

Operation

| Work Tool Circuits and Positions for the Rocker Switches One Pump Flow Two-Way Flow |

|

| Rocker Switch (A) | B |

| Rocker Switch (D) | F |

Move rocker switch (A) to position (B) . This de-energizes the solenoid for one pump/two pump flow (3) and the solenoid for one pump/two pump flow (4) . Move rocker switch (D) to position (F) . This energizes the solenoid for two-way flow (5) . This will also de-energize the solenoid for one-way flow (12) and the solenoid for one-way flow (13) .

Pilot pump (19) supplies oil to pilot manifold (23) . When the hydraulic activation lever is moved to the UNLOCK position, pilot oil flows from pilot manifold (23) to right foot pedal (6) .

When right foot pedal (6) is depressed FORWARD, pilot oil flows to auxiliary control valve (24) . The pilot oil will shift the spool in auxiliary control valve (24) to the DOWNWARD position. This allows oil from drive pump (20) to flow through the valve. The pump oil flows through the line for the work tool (14) to the work tool. The working pressure for the work tool is controlled by relief valve (25) . Return oil flows through the line for the work tool (15) and back to hydraulic tank (22) .

When right foot pedal (6) is depressed BACKWARD, pilot oil flows from pilot control valve (23) through the solenoid for two-way flow (5) . The pilot oil also flows to auxiliary control valve (24) . The pilot oil shifts the spool in auxiliary control valve (24) in the UPWARD position. This allows oil from drive pump (20) to flow through the valve. The pump oil flows through the line for the work tool (15) to the work tool. The working pressure for the work tool is controlled by relief valve (26) . Return oil flows through the line for the work tool (14) back to hydraulic tank (22) .

The pressure setting for the relief valves must be reset to the specification of the supplier for the work tool that is being used.

Two-Way Flow From Two Pumps “TOOL#4” and “TOOL#5”

Description

The default parameter values for “TOOL#4” and “Tool #5” are for two-way hydraulic oil flow from two main pumps. Refer to Testing and Adjusting, “System 11: Default Value of Work Tool Parameters” for the Tool Control System.

Operation

| Work Tool Circuits and Positions for the Rocker Switches Two Pump Flow Two-Way Flow |

|

| Rocker Switch (A) | C |

| Rocker Switch (D) | F |

Move rocker switch (A) to position (C) . This energizes the solenoid for one pump/two pump flow (3) and the solenoid for one pump/two pump flow (4) . Move rocker switch (D) to position (F) . This energizes the solenoid for two-way flow (5) . This will also de-energize the solenoid for one-way flow (12) and (13) .

Pilot pump (19) supplies oil to pilot manifold (23) . When the hydraulic activation lever is moved to the UNLOCK position, pilot oil flows from pilot manifold (23) to right foot pedal (6) .

When right foot pedal (6) is depressed FORWARD, pilot oil flows to auxiliary control valve (24) and to attachment control valve (17) . The pilot oil will shift the spool in each of the valves to the DOWNWARD position. This allows oil from drive pump (20) to flow through auxiliary control valve (24) and this allows oil from idler pump (21) to flow through attachment control valve (17) . The hydraulic oil from the two pumps combines after the oil passes through both valves. The pump oil flows through the line for the work tool (14) to the work tool. The working pressure for the work tool is controlled by relief valve (25) . Return oil flows through the line for the work tool (15) and back to hydraulic tank (22) .

When right foot pedal (6) is depressed BACKWARD, pilot oil flows from pilot control valve (23) through the solenoid for two-way flow (5) . The pilot oil then flows to auxiliary control valve (24) and to attachment control valve (17) . The pilot oil shifts the spool in each of the valves to the UPWARD position. This allows oil from drive pump (20) to flow through auxiliary control valve (24) and attachment control valve (17) . The hydraulic oil from the two pumps combines after the oil passes through both valves. The pump oil flows through the line for the work tool (15) to the work tool. The working pressure for the work tool is controlled by relief valve (26) . Return oil flows through the line for the work tool (14) back to hydraulic tank (22) .

The pressure setting for the relief valves must be reset to the specification of the supplier for the work tool that is being used.

Medium Pressure Circuit (Work Tool)

The medium pressure circuit for the work tool operates in the same manner for all machines. The descriptions refer to the operation of a rotating grapple. The medium pressure circuit can operate any work tool that utilizes an auxiliary circuit.

Drive pump (20) supplies hydraulic oil to the medium pressure circuit for rotation of the work tool. The medium pressure circuit is controlled by left foot pedal (7) . Left foot pedal (7) operates rotation only for “TOOL#2” and “TOOL#4”.

Pilot pump (19) supplies oil to pilot manifold (23) . When the hydraulic activation lever is moved to the UNLOCK position, pilot oil flows from pilot manifold (23) to left foot pedal (7) .

When left foot pedal (7) is depressed FORWARD, pilot oil flows to the auxiliary control valve (medium pressure) (27) . The pilot oil will shift the spool in the valve to the DOWNWARD position. This allows hydraulic oil from drive pump (20) to pass through the auxiliary control valve (medium pressure) (27) to medium pressure line (30) . The pump oil flows through medium pressure line (30) , to the rotate control valve for the work tool and to the motor for rotation. The working pressure for the medium pressure circuit is controlled by relief valve (29) . Return oil flows through the medium pressure line (31) and back to hydraulic tank (22) .

When left foot pedal (7) is depressed BACKWARD, pilot oil flows to the auxiliary control valve (medium pressure) (27) . The pilot oil will shift the spool in the valve to the UPWARD position. This allows hydraulic oil from drive pump (20) to pass through the auxiliary control valve (medium pressure) (27) to medium pressure line (31) . The pump oil flows through medium pressure line (31) , to the rotate control valve for the work tool and to the motor for rotation. The working pressure for the medium pressure circuit is controlled by relief valve (28) . Return oil flows through the medium pressure line (30) and back to hydraulic tank (22) .